Supply Chain Process Essentials: How to Optimize from Order to Delivery

The supply chain process is a complex journey that transforms raw materials into finished products, ready to reach the end consumer. From procurement and production to distribution and delivery, each step in the supply chain determines the quality and speed of service. In an age where technology and customer expectations evolve rapidly, companies like Amazon have set the bar high with their advanced supply chain optimization techniques. This blog will explore key strategies to enhance your supply chain process, ensuring efficiency and customer satisfaction from order to delivery.

The Phases of the Supply Chain Process

If you aren’t still convinced about the presence and significance of supply chain processes, let’s break down each phase that constitutes a “supply chain process.”

Overview of Critical Phases

The supply chain process is the intricate web of activities involved in getting a product from raw materials to the end customer.

- Planning and Demand Management: This is the brain of the operation. Businesses forecast customer demand, analyze sales trends, and plan inventory levels to ensure they have the right amount of materials on hand to meet that demand. In this context, supply chain planning comes in extremely handy, in terms of mapping the resources and keeping ready for the operations.

- Sourcing and Procurement: Here, the shopping list comes to life. Businesses identify and secure reliable suppliers for the raw materials and components needed for production. In terms of supply chains, sourcing, and procurement include establishing business with freight forwarders. It also involves negotiating competitive prices and establishing strong supplier relationships are key aspects of this phase.

- Making (Production): This is where the magic happens. Raw materials are transformed into finished goods through manufacturing or assembly processes. Quality control measures ensure products meet specifications.

- Delivering (Distribution): The finished goods need to reach the customer. This phase involves warehousing, transportation (trucks, ships, planes), and order fulfillment. Optimizing distribution routes and choosing the right transportation methods are crucial for efficiency and cost-effectiveness.

- Returning: Not every product reaches its final destination. This phase deals with returns management, including processing defective items, handling customer dissatisfaction, and potentially refurbishing or recycling returned goods.

Here it is important to note that these phases are not isolated as individual processes, rather, they ought to be carried out in unison, as elements of a single, cohesive system.

Also Read: What Is Supply Chain and How It Works?

Integration of Phases for Optimal Performance

It is obvious that a business processes several orders at a time; hence, coordination of each phase becomes crucial for the supply chain to operate as one. Here’s how they work together for optimal performance, referencing Newstreaming’s elements of supply chain management:

- Visibility and Information Sharing: Newstreaming emphasizes real-time data visibility across the supply chain. Information about demand forecasts (planning) feeds into sourcing decisions to ensure the right materials are procured. Similarly, production data can inform delivery schedules and identify potential bottlenecks.

- Collaboration and Relationship Management: Strong supplier relationships are vital for reliable sourcing. Collaboration extends to logistics partners for efficient delivery and potentially to after-sales service providers for returns management.

- Process Optimization: Newstreaming focuses on streamlining processes for efficiency. Data analysis from planning and demand management allows for optimized production scheduling (making). Additionally, efficient delivery routes and warehouse management contribute to overall process optimization.

- Agility and Risk Management: Unexpected events can disrupt the supply chain. Data-driven planning and sourcing strategies (from the first two phases) can help anticipate potential risks. Additionally, a flexible and adaptable approach to returns management helps minimize risks.

Also Read: Supply Chain Planning: What it is and How it works?

Key Elements of the Supply Chain Process

As we draw a full picture of the supply chain process while identifying various phases, it can further be deduced into the core elements that constitute these phases.

Core Components of Supply Chain Management

The smooth flow of goods from raw materials to customer satisfaction hinges on four core components working in perfect harmony: Integration, Operations, Purchasing, and Distribution. Each plays a vital role, and optimizing their function is the secret sauce of a successful supply chain.

- Integration: Integration acts as the conductor, ensuring all parts of the supply chain function in unison. Real-time data visibility across all stages is crucial. Sales data on customer demand can be readily relayed to purchasing to secure the right materials, preventing stockouts or overstocking. Inventory levels can be optimized based on production schedules, avoiding delays and waste.

- Operations: Operations are the heart of the supply chain, the engine that transforms raw materials into finished products. Accurate inventory and production schedules are paramount. Tight integration with the planning phase ensures smooth production flow, avoiding delays and minimizing waste. Additionally, efficient warehouse management within operations directly impacts distribution effectiveness.

- Purchasing: Securing the right materials at the right price is critical for cost control and efficiency. Purchasing acts as the supply chain’s negotiator, forging strong relationships with reliable suppliers. A well-defined sourcing strategy is key. Informed by data from various stages, purchasing secures the best deals on materials, contributing significantly to the overall competitiveness of the supply chain.

- Distribution: The most meticulously crafted product loses its value if it doesn’t reach the customer. Distribution is the final leg of the journey, ensuring efficient and timely delivery. Here, optimizing transportation routes and choosing the most suitable methods (e.g., trucks, ships, planes) is crucial. Streamlined distribution not only improves customer satisfaction but also reduces costs associated with unnecessary transportation delays or inefficiencies.

Also Read: Top Supply Chain Challenges You Must Address in 2025

Impact on Effectiveness and Competitiveness

Each element plays a vital role, impacting the overall effectiveness and competitiveness in a cascading manner. Strong integration ensures informed decisions across all stages, leading to optimized operations, strategic purchasing, and efficient distribution. Efficient operations directly translate to cost savings and a faster time-to-market, giving a business a competitive edge. Strategic purchasing practices not only secure quality materials but also control costs, further enhancing competitiveness. Finally, flawless distribution ensures timely deliveries and satisfied customers, which is the ultimate goal of any successful supply chain.

Operational Strategies in Supply Chain Management

While we equip ourselves with intricate details of the elements and phases of the supply chain processes, individually they add a limited value. However, in synergy, that extrapolates the impact on efficiency and is largely governed by the operational strategy.

Enhancing Logistics and Distribution

Logistics and distribution are imperative components in delivering products to your customers quickly and efficiently. Here are some strategies to improve these aspects, inspired by insights from Amazon’s business blog:

- Network Optimization: Analyze your distribution network and identify potential bottlenecks. Strategically locate warehouses closer to customer hubs to reduce delivery times. Consider utilizing smaller, regional fulfilment centres to improve last-mile delivery efficiency.

- Multimodal Transportation: Don’t rely solely on one mode of transport. Utilize a combination of trucks, trains, and even ships depending on the distance, urgency, and cost of delivery. Amazon leverages a complex network of transportation options to ensure efficient product movement.

- Inventory Management: Implement robust inventory management systems to maintain optimal stock levels. Leverage data analytics to predict demand fluctuations and prevent stockouts or overstocking.

- Route Planning and Optimization: Utilize route planning software to optimize delivery routes for drivers. This can minimize travel times, reduce fuel consumption, and ensure timely deliveries.

- Transparency and Visibility: Provide real-time tracking information to customers. This fosters trust and allows them to plan for deliveries.

Also Read: Understanding Supply Chain Analysis: Core Concepts and Advantages

Leveraging Technology for Efficiency

Advanced technologies are revolutionizing supply chain management. Here’s how some solutions can streamline processes:

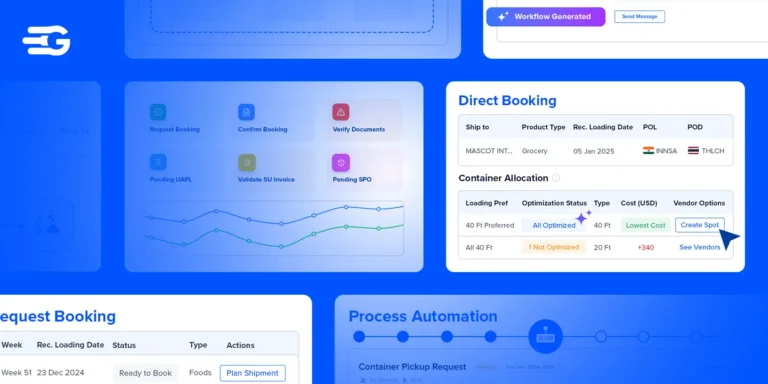

- Warehouse Management Systems (WMS): These software platforms automate warehouse operations, from inventory control to order fulfillment. GoComet offers a WMS solution that optimizes picking, packing, and shipping processes, leading to faster order fulfillment.

- Transportation Management Systems (TMS): These platforms manage the entire transportation lifecycle, from carrier selection to shipment tracking. GoComet’s TMS integrates seamlessly with their WMS, providing complete visibility into your supply chain.

- Artificial Intelligence (AI): AI can be used for demand forecasting, optimizing inventory levels, and even predicting potential disruptions within the supply chain. This allows for proactive decision-making and improved overall efficiency.

The Synergy Effect:

Combining these strategies with the power of technology creates a synergy that significantly improves logistics and distribution efficiency. Businesses can achieve faster delivery times, optimized transportation costs, and ultimately, a significant competitive edge.

Also Read: Top 12 Supply Chain Planning Software

Challenges and Solutions in Supply Chain Management

Common Supply Chain Challenges

The global supply chain, while a marvel of efficiency, faces numerous hurdles. Here are some of the most common challenges businesses encounter:

- Disruptions and Delays: Unexpected events like natural disasters, pandemics, or political unrest can significantly disrupt supply chains, leading to delays in production, transportation, and delivery.

- Cost Management: Balancing cost-effectiveness with quality materials and efficient operations can be a constant tightrope walk. Businesses face pressure to control costs while ensuring timely delivery and customer satisfaction.

- Demand Fluctuations: Accurately predicting customer demand is an ongoing challenge. Overestimating demand can lead to excess inventory and storage costs, while underestimating it can result in stockouts and lost sales.

- Risk Mitigation: The global nature of supply chains exposes them to various risks, such as currency fluctuations, trade restrictions, and supplier insolvency. Mitigating these risks requires proactive planning and diversification.

- Sustainability Concerns: The environmental impact of manufacturing and transportation is a growing concern. Businesses are under pressure to adopt sustainable practices throughout their supply chains.

Innovative Solutions to Overcome Challenges

These challenges require innovative solutions and best practices to ensure a resilient and sustainable supply chain:

- Supply Chain Visibility: Implementing real-time tracking systems and data analytics platforms provides greater visibility into the entire supply chain. This allows for proactive management of disruptions and quicker response times.

- Nearshoring and On-Shoring: Traditionally, businesses have looked to offshore production for cost savings. However, the recent focus on resilience is prompting a shift towards near sourcing (production in geographically closer countries) and even onshoring (domestic production) to reduce reliance on distant suppliers.

- Demand Forecasting with AI: Leveraging artificial intelligence and machine learning can improve demand forecasting accuracy. By analyzing vast amounts of data, AI can identify trends and predict customer behavior, allowing businesses to optimize inventory levels and production schedules.

- Supplier Relationship Management: Building strong relationships with reliable suppliers is key to mitigating risk. Businesses can diversify their supplier base and collaborate with suppliers to foster transparency and improve communication.

- Sustainable Practices: Implementing sustainable practices throughout the supply chain can minimize environmental impact. This includes using recycled materials, optimizing packaging, and adopting energy-efficient transportation methods.

Building Resilience and Sustainability

By adopting these solutions and best practices, businesses can build a resilient supply chain that can weather disruptions and adapt to changing circumstances. Additionally, an emphasis on sustainability ensures a positive environmental impact and strengthens a company’s brand image in the eyes of eco-conscious consumers.

But ever wondered to what extent? Here are some of case studies that stand as a testament to the importance of supply chain optimization.

Amazon’s supply chain optimization has allowed sellers to achieve up to 25% discounts on cross-border transportation and significantly reduced the storage fees to 80% lower than FBA storage fees. These cost reductions can lead to a direct boost in sales, with Amazon estimating a 15% increase in FBA unit sales when products are placed strategically for faster delivery.

During the period of the COVID-19 pandemic, Pfizer implemented a digital transformation initiative – the Global Supply-Digital Operations Center (DOC). This centralized hub provided real-time data on manufacturing and supply chains, allowing them to identify bottlenecks and reduce cycle times in key areas by up to 10%. This data-driven supply chain optimization transformed Pfizer into a more agile organization, proactively predicting and resolving supply chain issues before they impacted production.

According to McKinsey, an Asian life sciences company implemented a supply chain optimization program as a part of their Enterprise-wide platform transformation effort that identified over $250 million in potential savings across the entire value chain. This broader approach involved seven cross-functional teams and included initiatives like a new sourcing platform (70% of impact), a supply chain control tower for risk mitigation, and sales & operations planning for optimized inventory. The EPT approach went beyond technology upgrades to engage global teams and integrate business priorities, unlike a typical systems integration approach, which would have focused solely on IT and likely failed.

Such standardization of the supply chain process is mandatory, irrespective of the size and scale of the business, for the following reasons:

- Cost Reduction: By optimizing the supply chain, businesses can minimize waste, reduce inventory holding costs, and negotiate better pricing with suppliers.

- Improved Customer Satisfaction: Efficient delivery and availability of products enhance customer satisfaction.

- Increased Competitiveness: Businesses with streamlined supply chains can react faster to market changes and deliver products quicker than competitors.

- Global Reach: A well-managed supply chain allows businesses to source materials and manufacture products in different parts of the world, taking advantage of cost benefits and market opportunities.

Despite the standardization and surface-level concrete nature of supply chain processes, they remain highly open to optimization with advancing technology. The integration of supply chain management systems has revolutionized supply chain optimization by leveraging AI-enabled tools. These systems incorporate real-time data analysis to predict and prevent disruptions, optimize inventory levels across the network, and recommend the most efficient transportation routes, enabling businesses to achieve unparalleled efficiency and resilience.

Future Trends in Supply Chain Management

The future of supply chain management is brimming with innovation. Generative AI (GenAI) can optimize inventory, and production and ensure compliance. AI-enabled low-touch planning will automate tasks and leverage data analytics. Data will be crucial for informed decisions and meeting ESG goals. Transparency beyond Tier 1 and 2 will improve visibility and risk mitigation. Low-code platforms will enable faster development and adaptation. A focus on ESG and Scope 3 emissions will require collecting data from suppliers. Electric vehicles and automation will transform transport and logistics. Organizations that embrace these trends will be better positioned for success.

Conclusion

The supply chain landscape is undergoing a revolution. AI, data analytics, and automation are transforming how businesses manage their operations. Embracing these trends will be critical for future success. By harnessing technologies like generative AI for planning and low-code platforms for agility, businesses can optimize efficiency and build resilience.

Transparency beyond Tier 1 suppliers and a focus on ESG will become key differentiators. The future belongs to those who adapt and leverage innovation. Optimizing your supply chain isn’t just about efficiency today. It’s about unlocking a competitive edge for tomorrow.