A dock scheduling optimization approach for enhancing logistics efficiency

Loading docks are an integral nodal point in the supply chain, be it planes, trucks, or ships, they need to make a landing contact, unload, reload, and get going.

Did you carve out a simple assembly line of vehicles and vessels? Well, notch the traffic up by at least 10x and wonder what can be the commotion around.

Dock scheduling is a traffic control system for warehouses and distribution centers. It’s coordinating the arrival and departure of trucks, assigning them specific time slots and dock doors. This goes beyond just picking a random time. Dock scheduling eliminates congestion by ensuring there’s a designated space and workforce ready for each truck upon arrival. This keeps everything moving smoothly and efficiently.

Further, trucks waiting for hours to be loaded or unloaded cost money. Dock scheduling minimizes these wait times, bringing down detention fees, keeping drivers happy, and reducing labor costs associated with handling unscheduled arrivals.

In today’s complex supply chains, where efficiency is paramount, dock scheduling plays a critical role in keeping things running like a well-oiled machine. It ensures resources are used effectively, costs are controlled, and everyone involved in the logistics chain experiences a smoother, more predictable process.

Why is dock scheduling important?

Enhancing Operational Efficiency

Effective dock scheduling streamlines the entire warehouse loading and unloading processes. By knowing what’s coming in each truck (type and volume of goods), the warehouse can pre-assign the right crew and equipment (like forklifts) to the specific dock door. This eliminates scrambling and delays when trucks arrive.

Dock schedules also consider internal workflows like picking and packing. With pre-determined arrival times, picking and packing teams can be strategically scheduled to have goods ready when trucks arrive for loading. This synchronization eliminates bottlenecks and keeps the entire warehouse operations flowing smoothly.

Finally, dock scheduling removes uncertainty by providing a clear picture of daily or weekly truck arrivals. This predictability allows warehouse managers to effectively plan staff schedules, ensuring they have enough manpower to handle the incoming and outgoing flow of goods, preventing delays and frustration from understaffing.

Reducing Wait Times and Congestion

Warehouses and the entire supply chain reap significant benefits from minimizing wait times and congestion at docking areas. Firstly, dock scheduling keeps detention fees in check by ensuring trucks aren’t stuck idling for hours. This not only saves money but fosters better relationships with carriers.

Happier drivers are another perk, as reduced wait times mean more time spent on deliveries. This translates to improved driver retention for carriers, leading to a more reliable workforce. The domino effect of delays is also eliminated with smooth traffic flow thanks to dock scheduling. This optimizes the use of dock doors and warehouse resources, enhancing overall efficiency.

Eventually, streamlined dock operations minimize the risk of damage to goods by reducing congestion and the chaos that comes with it. By prioritizing efficient dock scheduling, everyone wins – warehouses, carriers, and ultimately, the customers who receive their deliveries on time.

Understood that dock management is mandatory, but given such utility, what are the specific components of dock scheduling?

Appointment Scheduling

The groundwork for dock scheduling is laid through meticulous appointment scheduling for deliveries and pickups. This electronic dance starts with carriers or shippers requesting a specific time slot to load or unload their goods.

They typically include details like expected arrival time, type of goods, and volume. The warehouse team then assesses this request against their available docks. They consider factors like dock door capacity, staff schedules, and the equipment needed for the specific goods.

Based on this evaluation, the warehouse allocates a suitable time slot and dock door to the carrier, sending electronic confirmation with the agreed-upon arrival and departure times.

Resource Allocation

Allocating the correct resources is vital for efficient dock operations in warehouse scheduling. By knowing the type and volume of goods arriving with each truck, the warehouse can pre-assign the necessary personnel (forklift operators, dockworkers) and equipment (forklifts, pallet jacks) to the specific dock door.

This eliminates last-minute scrambling and delays, ensuring a smooth and efficient loading/unloading process.

Furthermore, having the right resources readily available maximizes the throughput of each dock, leading to faster turnaround times for trucks and minimizing congestion reducing the risk of damage to goods and promoting a safe work environment.

Real-Time Communication

In case of delays, traffic jams, or adjustments to shipment size, real-time supply chain visibility software ensures that warehouses are notified immediately. This empowers them to proactively adjust schedules, inform carriers, and minimize disruptions to operations. Additionally, real-time data on truck locations and estimated arrival times provides warehouse managers with comprehensive end-to-end visibility of the supply chain, enhancing efficiency and decision-making.

This translates to informed decisions about resource allocation and the ability to adapt to changing circumstances on the fly. Ultimately, effective communication fosters collaboration between warehouse staff, carriers, and even customers. This collaborative approach ensures everyone is on the same page, leading to smoother operations and a happier customer experience.

How do these components culminate to benefit the supply chain operations?

Improved Visibility and Control

Dock scheduling isn’t just about assigning time slots; it’s about gaining a clear picture and control over your warehouse operations. Modern systems provide real-time data on truck locations and arrival estimates, giving warehouse managers visibility into upcoming activity. This allows for proactive resource allocation, improved inventory coordination to ensure goods are ready for loading, and data-driven decision-making to optimize dock usage and overall logistics efficiency and optimization.

Enhanced Customer Satisfaction

Dock scheduling translates to happy customers. By minimizing delays and ensuring on-time deliveries, customers receive their orders reliably. Additionally, streamlined operations reduce errors during loading, leading to accurate and complete deliveries. The real-time communication facilitated by dock scheduling allows warehouses to proactively inform customers of any potential issues, fostering trust and stronger relationships.

Cost Reduction

Efficient dock scheduling goes beyond smooth operations. It translates to significant cost savings. Warehouses can minimize expensive detention fees by reducing truck wait times. Proper scheduling allows for optimized labor allocation, eliminating unnecessary costs from over or understaffing. Finally, streamlined dock operations decrease the risk of damage to goods, reducing replacement costs and customer returns.

The sheer components included in dock scheduling can make the entire operation cumbersome. Are there any better ancillaries that can implement dock scheduling?

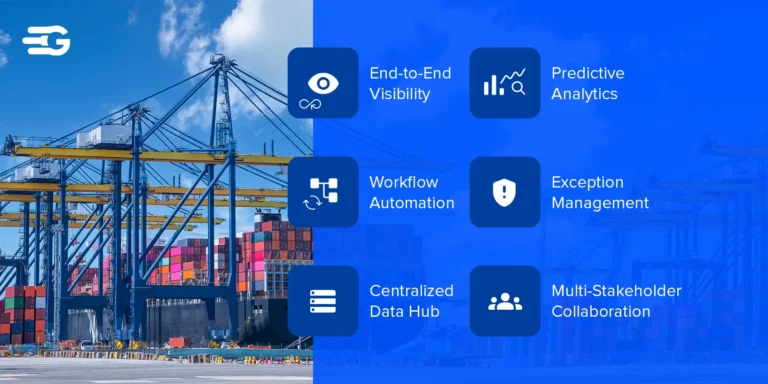

GoComet is one of the noted service ancillaries that can integrate specifics of dock scheduling. GoComet’s dock scheduling solutions offer a robust set of features designed to streamline warehouse operations and enhance efficiency.

Here’s a glimpse of some key functionalities:

- Real-time Visibility: Gain real-time insights into upcoming deliveries and pickups with truck location tracking and estimated arrival times. This allows for proactive resource allocation and improved dock utilization.

- Appointment Scheduling: Electronically manage appointment requests from carriers, considering factors like dock availability, staff schedules, and goods type. Allocate suitable time slots and dock doors for smooth arrival and departure.

- Resource Management: Optimize labor and equipment allocation by pre-assigning the right personnel and equipment (forklifts, pallet jacks) to each dock door based on the incoming goods.

- Automated Notifications: Keep everyone informed with automated notifications about arrival times, potential delays, and dock assignments. This fosters real-time communication and streamlines operations.

- Data-Driven Insights: Generate reports that provide valuable data on dock utilization, loading/unloading times, and potential bottlenecks. Leverage this data to identify areas for improvement and make data-driven decisions for enhanced logistics efficiency.

Integration with Existing Systems

GoComet’s dock scheduling solutions aren’t designed to operate in isolation. They integrate seamlessly with your existing warehouse (WMS) and logistics management systems (LMS) for a smoother flow of information. This eliminates data silos, those frustrating information bubbles.

Real-time data zips between GoComet and your existing systems, eliminating manual entry and reducing errors. The integration also streamlines workflows ensuring goods are ready for loading as and when the vessels and vehicles arrive.

However, there will be some sensitive areas in dock scheduling that have the potential to hinder smooth operations, what are they and how do we handle them?

Managing Peak Times and High Volumes

Despite the reading and infrastructure, peak seasons and unexpected shipment surges expose vulnerabilities in dock scheduling systems. A sudden influx of trucks can overwhelm dock capacity, leading to cascading delays, frustrated drivers, and a domino effect disrupting the entire schedule. These peak periods strain resources.

Ensuring the right personnel and equipment are available at each dock becomes a challenge as staff and equipment are stretched thin. In such a scenario, clear communication between warehouse staff, carriers, and potentially customers can break down under pressure, causing misunderstandings, missed appointments, and further delays.

Ensuring Data Accuracy

Effective dock scheduling hinges on accurate data. Inaccurate information on factors like arrival times, shipment volumes, and goods type leads to a domino effect. Poor slot allocation and resource misallocation create chaos.

Precise data on incoming goods allows for optimal pre-assignment of personnel and equipment, preventing delays and potential damage. Real-time data on truck locations and arrival estimates provide vital visibility for proactive resource allocation and adapting to unforeseen circumstances. This focus on data integrity ensures optimal dock scheduling function, even during peak periods.

Given that updation with the concurrent technologies is an undercurrent, how does the future look for dock scheduling?

AI and Machine Learning

Dock scheduling is undergoing an AI and machine learning revolution. ML algorithms crunch historical data on arrival times, loading times, and shipment volumes to predict future dock activity and identify potential bottlenecks. This foresight empowers proactive adjustments to schedules and resource allocation, preventing disruptions before they arise.

AI automates slot allocation by analyzing appointment requests and real-time data to assign optimal dock doors and times. This eliminates manual scheduling, saving time and reducing human error.

ML continuously monitors dock operations in real time, identifying delays and unexpected situations. These insights allow for dynamic schedule adjustments, ensuring optimal resource allocation and smooth operation even amidst disruptions.

IoT and Real-Time Tracking

IoT is supercharging dock scheduling with real-time tracking. Sensors on trucks, trailers, and even within the warehouse provide constant updates on location, temperature, and potential equipment issues. This translates to pin-point precision in tracking arrivals, allowing for better anticipation of loading/unloading times.

IoT automates data collection on dock usage and equipment status, eliminating error-prone manual entry and ensuring the data accuracy crucial for effective scheduling. The real win comes from proactive problem-solving. Real-time data enable broader visibility and can trigger preventive maintenance on malfunctioning equipment before it disrupts operations, and traffic data can be used to identify delays and adjust schedules accordingly.

The Strategic Advantage of Dock Scheduling

Inefficient dock operations can cripple your logistics. Dock scheduling offers a cure, streamlining your warehouse and boosting efficiency. Reduced wait times at docks lead to happier customers with on-time deliveries. Smart allocation of labor and resources, guided by real-time data, keeps costs down and operations flowing smoothly.

Dock scheduling grants you superior visibility into your entire logistics operation, allowing for proactive decision-making and fewer errors. The result? A well-oiled logistics machine that saves you money and keeps your customers delighted. Don’t let your dock be a roadblock – implement dock scheduling and watch your efficiency take off.