Understanding GoTrack: Container Tracking Software

Imagine the constant struggle: logging into countless carrier websites, managing a sea of login credentials, and making endless phone calls for each shipment. This is the unfortunate reality of manual shipment tracking – a time-consuming maze that leaves you uncertain about the whereabouts of your valuable cargo.

Fragmented Visibility: Your current process likely involves maintaining a list of containers in transit, followed by tedious tracking on individual shipping line websites. This fragmented approach lacks a centralized view and requires manual follow-up from various teams.

Prone to Errors: Manual data entry and tracking are inherently susceptible to human error. These errors can lead to delays, missed deadlines, and ultimately, unnecessary costs.

Wasted Productivity: Hours are lost navigating disparate systems and managing logins. Studies have shown that an employee spends 3 hours a day performing manual data entry which leads to a loss of 753 hours a year.

Financial Risks Abound:

Errors in manual shipment tracking can lead to a domino effect of financial setbacks. Inaccurate information can significantly delay locating shipments, impacting delivery schedules and potentially incurring costly demurrage/detention charges at ports.

Beyond these specific costs, there are also the broader financial implications of human error. A study by global analyst firm IDC revealed that human error costs businesses in the United States and the United Kingdom an average of $435 per employee annually. When extrapolated to a company’s entire workforce, this translates into significant financial losses.

GoTrack: Your Data-Driven Supply Chain Arsenal

GoTrack by GoComet transcends mere software, acting as a transformative supply chain revolution. We understand the critical need for real-time visibility and peace of mind. That’s why GoTrack streamlines shipment tracking, offering a comprehensive view of your cargo’s whereabouts, all delivered in an intuitive, user-centric interface.

This allows us to prioritize clarity, displaying all essential shipment data in a readily digestible format. With GoTrack, you can make informed decisions quickly and efficiently, keeping you in complete control of your supply chain.

Effortless Integration: Forget about complex software implementations that disrupt your daily operations. GoTrack is designed for seamless integration with your existing systems, minimizing downtime and maximizing efficiency.

Our plug-and-play approach utilizes industry-standard APIs to connect effortlessly with your existing infrastructure. This eliminates the need for costly and time-consuming custom development, allowing you to get up and running quickly and seamlessly

Intelligent Data Capture: Streamline your workflow and free your employees from tedious data entry tasks. GoTrack’s intelligent data capture system allows you to enter shipment details once, eliminating the need for repetitive input across multiple carrier websites.

Our system automatically populates relevant fields and leverages pre-populated information, minimizing errors and saving you valuable time. This allows your team to focus on core business activities that drive growth and profitability.

Real-Time Visibility & Streamlined Workflows: Say goodbye to the inefficiency of juggling multiple carrier websites and struggling to obtain a consolidated view of your shipments. GoTrack provides a single, user-friendly platform that offers real-time visibility into all your shipments, regardless of the carrier.

This centralized dashboard empowers you to track shipment progress, identify potential delays, and manage exceptions with ease. Our intuitive interface simplifies complex information, allowing your team to make informed decisions quickly and efficiently. The streamlined workflow translates to significant time savings and enhanced operational efficiency, enabling you to focus on strategic initiatives.

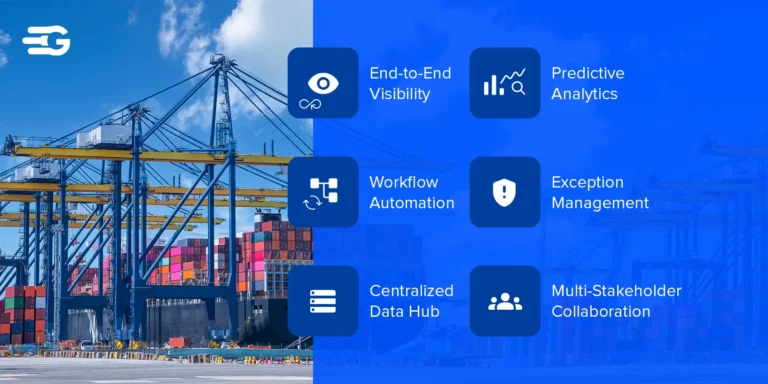

In fact, GoTrack goes beyond basic tracking, offering a robust suite of features powered by data intelligence to transform your operations.

Automated Notifications: Receive instant alerts for delays, exceptions, or any unforeseen circumstances. This proactive approach empowers you to take swift action, mitigate disruptions, and minimize potential losses.

Automated Customer Updates: Foster improved customer service by automatically keeping consignees informed with notifications two days prior to shipment arrival. This transparency allows them to adjust their plans accordingly, reducing the likelihood of missed deliveries or frustrated customers.

Data-Driven Decision Making: GoTrack doesn’t just track your shipments, it unlocks valuable insights. Leverage historical data and comprehensive tracking reports to identify trends and optimize your supply chain. Make data-driven decisions that improve efficiency, reduce costs, and give you a competitive edge.

Predictive ETAs: Powering Proactive Logistics

GoTrack’s Predictive ETA feature harnesses the power of AI to provide more accurate and reliable estimates of arrival times (ETAs), ensuring smooth and efficient supply chain operations. Our solution goes beyond basic tracking by integrating multiple data sources to create a comprehensive picture of your shipment’s journey. Here’s what sets GoTrack’s Predictive ETA apart:

Multi-Source Data Integration

Past Carrier Performance: Historical data on carrier performance in similar lanes helps in making informed predictions about future shipments.

Real-Time Vessel Tracking: Leveraging AIS data (Automatic Identification System), we continuously monitor the position and movement of vessels, providing real-time insights into their progress.

Port Congestion Levels: Real-time and historical data on port congestion allows us to dynamically adjust ETAs, accounting for potential delays.

Carrier Schedules: By incorporating schedules from various carriers, GoTrack provides a holistic view of the entire transportation process, enabling precise ETA calculations.

AI-Powered Processing

These data points are ingested by our advanced AI engine, which processes and analyzes them to deliver highly accurate ETAs.

Proven Results

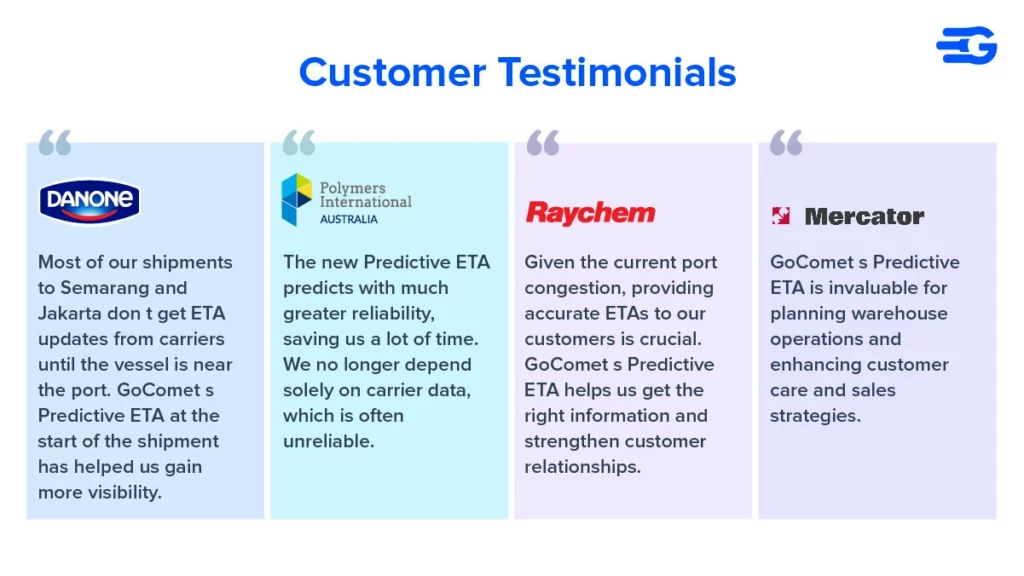

20% More Accurate ETAs: Our predictions are 20% more accurate compared to traditional carrier-provided ETAs, from the start of the shipment, giving you a clearer picture of arrival times from the outset.

45% Greater Coverage: We provide 45% more coverage in terms of lanes and shipments tracked, ensuring that a wider range of your shipments benefit from accurate predictions and real-time monitoring.

Proactive Delay Management: Mitigate Disruptions Before They Occur

One of GoTrack’s most transformative features is its ability to identify potential delays well before they disrupt your operations. This proactive approach empowers you to take preventative measures and minimize the impact on your business with 30% fewer stockouts and 25% lower inventory carrying costs.

Probable Delay: Your Early Warning System

GoTrack continuously monitors your shipments against their planned arrival schedules, leveraging historical data and real-time logistics insights. If a shipment’s arrival status isn’t updated within a statistically expected window, GoTrack flags it as a “Probable Delay.”

This critical early warning allows you to:

Investigate the Cause: Proactively reach out to the carrier to understand the potential reason behind the delay. This information can help you determine the severity and potential duration of the issue.

Communicate Proactively: Inform consignees about the potential delay as soon as possible. Transparency allows them to adjust their plans accordingly, potentially reducing the impact on their operations.

Prepare for Impact: Depending on the nature of the delay and the criticality of the shipment, you may need to make adjustments to minimize disruptions. This could involve expediting alternative shipments, adjusting production schedules, or informing customers of potential impacts on delivery timelines.

Confirmed Delay: Taking Action When Necessary

While GoTrack strives to identify potential delays early on, unforeseen circumstances can sometimes lead to confirmed schedule changes by carriers. When GoTrack detects a revised schedule through real-time data analysis, it automatically updates the shipment status to “Delayed.”

With instant notification of confirmed delays, you can:

Assess the Impact: Evaluate the extent of the delay and its potential ripple effects on your operations. This allows you to prioritize actions and minimize disruptions to your production lines or customer deliveries.

Implement Adjustments: Depending on the severity of the delay, take corrective actions to minimize disruption. This could involve expediting alternative shipping options, negotiating with the carrier, or adjusting production schedules.

Maintain Transparency: Keep all stakeholders informed about the confirmed delay. This fosters trust with your customers and manages expectations, reducing potential frustration and reputational risks.

By providing both “Probable Delay” and “Confirmed Delay” notifications, GoTrack empowers you to take a proactive approach to delay management. This proactive strategy can significantly minimize the impact of disruptions on your business and ensure a smoother, more efficient supply chain.

GoTrack’s Geofencing Advantage

Geo fencing is a location-based service (LBS) technology that uses geographical coordinates to create a virtual boundary around a real-world location. This innovative approach allows Go Track to provide visibility into your cargo’s real-time location, even in situations where carrier websites lack sufficient data or updates.

Here’s how GoTrack’s geofencing advantage empowers you:

Real-Time Vessel Data Integration: GoTrack integrates seamlessly with the Automatic Identification System (AIS). This global tracking network transmits real-time information on the movement of vessels worldwide. By incorporating this data feed, GoTrack offers a more comprehensive picture of your shipment’s journey.

Destination Port Targeting: GoTrack doesn’t rely solely on carrier updates. It actively compares the real-time AIS data with the location coordinates of your shipment’s designated destination port. This proactive approach allows GoTrack to anticipate the shipment’s arrival time frame accurately.

Virtual Perimeter Creation: Employing Geofences: Leveraging the combined power of AIS data and destination port targeting, GoTrack creates a virtual fence, or geofence, around the destination port. This 20-kilometer radius of the geofence serves as a virtual trigger, allowing GoTrack to monitor when your shipment enters the designated zone.

Enhanced Visibility and Timely Notifications: When your shipment enters the geofence surrounding the destination port, GoTrack triggers an immediate notification. This real-time alert provides valuable confirmation that your cargo is nearing its final destination, even if carrier updates are delayed or unavailable.

Achieve Supply Chain Harmony with GoTrack

By combining these powerful features, GoTrack empowers you to orchestrate a harmonious and efficient supply chain.

Reduced Costs: GoTrack’s proactive approach allows for the early identification of potential delays. This enables you to take corrective actions that minimize demurrage/detention charges, expediting fees, and other unforeseen cost overruns.

Enhanced Operational Efficiency: Proactive problem-solving is at the core of GoTrack’s philosophy. By anticipating potential disruptions, you can maintain smooth operations and avoid disruptions in your production or delivery schedules. This translates to a streamlined supply chain with maximized efficiency.

Elevated Customer Service: Keeping consignees informed about potential delays fosters stronger relationships and builds trust. GoTrack’s automated notifications empower you to communicate proactively, allowing your customers to adjust their plans accordingly and minimize disruptions on their end.

Plenty of Fish in the Sea: Why Go Comet?

In the crowded world of shipment tracking software, GoTrack by GoComet stands out from competitors like Project 44 and FourKites. While all offer robust features, GoTrack shines with its superior combination of accuracy, live updates, and unmatched coverage. Here’s why GoTrack surpasses the competition:

Unmatched Coverage & Real-Time Updates: Unlike competitors who struggle with slow update cycles, GoTrack boasts industry-leading coverage with real-time data feeds. This means you get the most up-to-date information on your shipments, regardless of carrier or location.

Proactive Delay Management: GoTrack goes beyond basic tracking by offering “Probable Delay” alerts. This proactive approach warns you of potential issues before they disrupt your operations, allowing you to take corrective action and manage customer expectations effectively.

Superior Visibility with Geofencing: GoTrack’s unique geofencing technology provides real-time insights even in situations where carrier websites fall short. This crucial edge in visibility allows you to plan for arrival and follow-up processes with confidence.

Accuracy You Can Trust: GoTrack prioritizes data accuracy to ensure you have the most reliable information at your fingertips. This translates to better decision-making and a more efficient supply chain.

Whether you prioritize user-friendly implementation, proactive problem-solving, or superior visibility, GoTrack equips you with the tools to champion your supply chain strategy.

See How Kodak Used GoTrack to Revolutionize Their Shipments

Kodak’s struggle with manual shipment tracking mirrored the common pain points we outlined earlier. They were grappling with a labyrinth of carrier websites, time-consuming updates, and limited visibility into their shipments’ whereabouts.

GoTrack became their champion, streamlining the process. Real-time data replaced the need for constant follow-up calls, and AI-driven insights from GoTrack empowered Kodak to make crucial cost-saving decisions by identifying top-performing routes and carriers.

With GoTrack, Kodak wasn’t left in the dark – automated notifications kept them informed of potential delays, allowing them to proactively manage customer expectations and internal logistics. This shift from a reactive to a proactive approach, facilitated by GoTrack’s features, is a prime example of how GoComet empowers businesses to transform their supply chains.

By replacing the chaos of manual tracking with a data-driven, user-friendly platform, GoTrack empowers businesses to achieve significant results. Just like Kodak, over 220 enterprise clients have discovered the championing power of GoTrack. They’ve collectively saved a staggering $69 million and a mind-boggling 150 million minutes – a testament to GoTrack’s ability to streamline operations and free up valuable resources.

Are you ready to ditch the frustration of manual tracking and become a GoTrack champion? Try GoTrack today and experience the difference for yourself.