The Future of Supply Chain Control Towers: Trends to Watch in 2025 and Beyond

In today’s fast-paced global market, supply chains are no longer just about moving goods from point A to point B. Instead, they have evolved into complex, dynamic ecosystems that require real-time insights, advanced analytics, and a high degree of agility. Supply chain control towers have emerged as the nerve centers of these ecosystems, providing end-to-end visibility, proactive risk management, and strategic decision-making capabilities. As we look toward 2025 and beyond, several key trends are set to redefine how control towers operate—and at the forefront of these changes is technology and innovation, with players like Gocomet driving next-level solutions.

Evolving from Reactive to Proactive Management

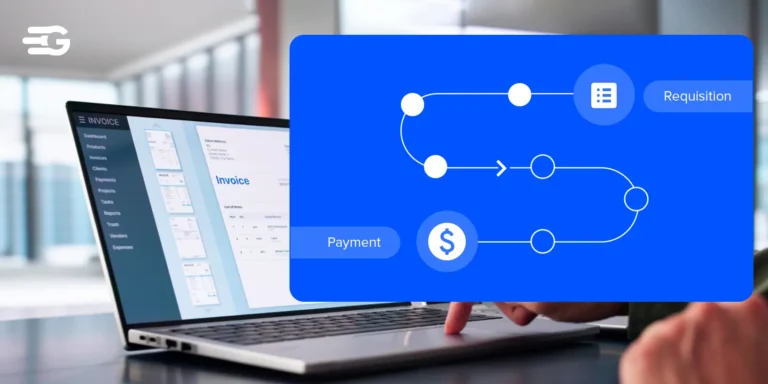

Historically, supply chain management was a reactive discipline. When disruptions occurred, companies scrambled to fix issues after the fact. Today, the paradigm has shifted. The era of reactive supply chain management is over. Modern control towers now leverage real-time data, predictive analytics, and artificial intelligence (AI) to foresee potential problems and initiate preventive measures.

The Power of Real-Time Visibility and Predictive Analytics

Control towers equipped with real-time monitoring systems allow organizations to track inventory, shipments, and supplier performance minute by minute. Advanced predictive analytics help companies simulate various “what-if” scenarios, ensuring that they are not only aware of current conditions but are also prepared for future challenges. By predicting disruptions—ranging from supplier delays to geopolitical shifts—control towers empower decision-makers to act before issues escalate.

For example, integrating a digital twin of the entire supply chain provides a virtual environment where businesses can test contingency plans and optimize operations under different scenarios. This proactive approach ensures that companies are always one step ahead, reducing downtime and minimizing costs.

Integrating Digital Twins and Advanced Simulation Techniques

One of the most significant technological advances reshaping supply chain control towers is the integration of digital twins. A digital twin is a virtual replica of a company’s supply chain network. It allows organizations to simulate and analyze the impact of various disruptions and operational changes before they occur in the real world.

Benefits of Digital Twins in Supply Chain Management

Enhanced Scenario Planning: Digital twins enable supply chain professionals to model and test multiple scenarios—ranging from demand fluctuations to supplier disruptions—ensuring that contingency plans are robust and well-informed.

Optimized Inventory Flows: By simulating different supply chain configurations, businesses can fine-tune their inventory management strategies, striking the right balance between excess stock and potential shortages.

Informed Decision-Making: With the ability to visualize the entire network and forecast potential bottlenecks, decision-makers can act swiftly, reallocating resources and adjusting strategies in real time.

This simulation capability is essential in today’s volatile market, where unforeseen events—such as natural disasters or sudden policy changes—can rapidly alter supply dynamics. Digital twins offer a proactive safeguard, ensuring that supply chain control towers remain agile and responsive.

Navigating Geopolitical Shifts and Trade Uncertainties

Geopolitical tensions and evolving trade policies have become defining characteristics of the global supply chain landscape. Trade wars, tariffs, and shifting international alliances introduce layers of complexity that can disrupt even the most well-planned operations.

Strategic Approaches to Global Trade Disruptions

Diversification of Supplier Networks: In today’s uncertain geopolitical climate, relying solely on suppliers from regions prone to trade disputes is risky. Companies must map their entire supplier network—from first-tier to sub-tier suppliers—and identify alternative sources in more stable regions.

Advanced Inventory Optimization: Utilizing demand sensing and multi-echelon inventory optimization tools can help balance stock levels and manage costs effectively. By aligning inventory with real-time demand, companies can mitigate the risks associated with sudden trade policy changes.

Real-Time Trade Data Integration: Modern control towers are incorporating global trade management systems that provide instant access to updates on trade regulations, tariffs, and international agreements. This ensures compliance and enables rapid adjustments to sourcing strategies.

These strategies not only mitigate risk but also offer a competitive edge, as companies that can adapt quickly to geopolitical shifts are more likely to thrive in uncertain times.

Sustainability and Regulatory Compliance in a Changing World

Sustainability has transitioned from being a “nice-to-have” feature to an essential component of supply chain strategy. Governments and consumers alike are demanding greater transparency, reduced environmental impact, and ethical sourcing practices. For supply chain control towers, this means integrating Environmental, Social, and Governance (ESG) considerations into every aspect of operations.

Meeting ESG Goals Through Technology

Supplier Visibility: Technologies that map and track suppliers help companies ensure that every link in their supply chain meets rigorous ESG standards. This visibility is crucial for compliance with international regulations, such as the European Union’s Carbon Border Adjustment Mechanism (CBAM) and the U.S. Uyghur Forced Labor Prevention Act (UFLPA).

Real-Time Compliance Monitoring: Control towers can leverage compliance-specific technologies to continuously monitor regulatory changes and assess potential risks. This proactive monitoring prevents costly fines and reputational damage.

Sustainable Operations: By integrating sustainability metrics into their operational dashboards, companies can make informed decisions that align with both business goals and environmental responsibilities.

Incorporating sustainability into supply chain management not only fulfills regulatory requirements but also builds trust with customers and investors. It creates a resilient, future-proof supply chain that is adaptable to emerging market demands.

Customer-Centricity: The Heart of Modern Supply Chains

In an age where customers demand immediate gratification and transparency, supply chains must evolve to become customer-centric. The modern consumer expects fast delivery, real-time tracking, and personalized service—expectations that traditional supply chain models struggle to meet.

Enhancing Customer Experience Through Control Towers

Real-Time Order Tracking: By providing customers with end-to-end visibility of their shipments, companies can enhance trust and satisfaction. Control towers offer a centralized platform for tracking orders, ensuring that any delays or issues are communicated promptly.

Personalized Delivery Options: Leveraging historical data and predictive analytics, control towers can offer tailored delivery options that meet individual customer preferences. Whether it’s expedited shipping or flexible delivery windows, personalized solutions help build long-term loyalty.

Carrier Collaboration: A robust control tower strategy involves partnering with multiple carriers to ensure redundancy and resilience. This flexibility minimizes the impact of disruptions and ensures that packages are delivered on time, every time.

Ultimately, a customer-centric approach transforms the supply chain from a cost center into a strategic asset, driving growth and enhancing brand reputation.

The AI Revolution: Composite and Agentic AI in Supply Chain Control Towers

Artificial intelligence (AI) is at the forefront of the next wave of supply chain innovation. Early generative AI tools have given way to more sophisticated technologies—composite AI and agentic AI—that are reshaping the operational landscape of control towers.

What Composite and Agentic AI Bring to the Table

Composite AI: This approach combines multiple AI technologies to provide holistic, data-driven insights. By integrating data from diverse sources—such as historical trends, real-time sensor data, and market forecasts—composite AI offers a comprehensive view of the supply chain. This fusion of data streams enhances predictive accuracy and informs better decision-making.

Agentic AI: Unlike traditional AI systems that merely provide insights, agentic AI can take autonomous actions based on real-time data. This capability allows control towers to not only predict disruptions but also to automatically implement corrective measures without waiting for human intervention.

The integration of these advanced AI systems is transforming supply chain control towers from passive monitoring hubs into active, self-correcting networks. Companies that harness these technologies can achieve unprecedented levels of efficiency and responsiveness.

Spotlight on GoComet: Driving Next-Level Supply Chain Innovation

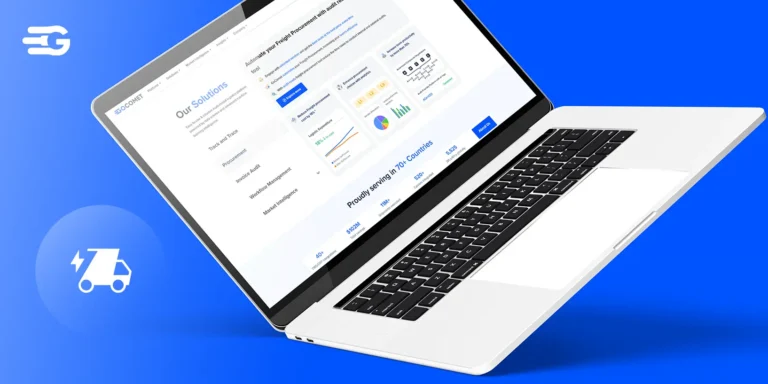

Among the innovators in the space, Gocomet stands out as a trailblazer in enhancing supply chain control towers. Gocomet’s platform leverages state-of-the-art technology to offer real-time visibility, robust analytics, and actionable insights—capabilities that are critical in today’s dynamic supply chain environment.

How GoComet Elevates Supply Chain Control Towers

Integrated Visibility: Gocomet’s solution is designed to integrate seamlessly with existing control tower frameworks, providing a unified view of the entire supply chain. This integration ensures that data from multiple sources—ranging from transportation management systems to supplier networks—is consolidated into a single, actionable dashboard.

Advanced Analytics and AI: By harnessing advanced analytics and AI, Gocomet transforms raw data into meaningful insights. Their platform can predict potential disruptions, optimize routing, and even recommend adjustments to inventory levels in real time.

User-Friendly Interface: Recognizing that technology must be accessible to drive adoption, Gocomet offers an intuitive interface that allows supply chain professionals to quickly interpret data and make informed decisions. This user-centric design ensures that even complex insights are easily actionable.

Scalability and Flexibility: As supply chains continue to grow in complexity, scalability becomes essential. Gocomet’s solution is built to adapt, handling everything from small-scale operations to global networks, all while maintaining robust performance and reliability.

In a world where supply chains are becoming increasingly interconnected and complex, Gocomet provides the technological edge that organizations need to stay ahead. Their innovative approach not only enhances traditional control tower capabilities but also paves the way for the next generation of supply chain management.

Looking Ahead: Adaptability, Innovation, and Resilience

The future of supply chain control towers is dynamic, shaped by continuous technological advancements and an ever-changing global landscape. The trends discussed—proactive risk management, digital twin integration, geopolitical navigation, sustainability, customer-centricity, and AI innovation—are setting the stage for a new era in supply chain management.

Key Takeaways for Organizations Preparing for 2025 and Beyond

Embrace Proactivity: Transitioning from reactive to proactive management is essential. Utilize real-time data and predictive analytics to anticipate disruptions and implement preemptive measures.

Invest in Digital Transformation: Technologies like digital twins and advanced simulation tools are not just optional—they are vital for building a resilient and agile supply chain.

Diversify and Optimize: Navigating geopolitical uncertainties requires diversified supplier networks and intelligent inventory optimization strategies that can adapt to shifting market conditions.

Prioritize Sustainability: Regulatory pressures and consumer expectations demand that ESG and sustainability be integral to supply chain operations. Use technology to monitor and enhance compliance continuously.

Center the Customer: Delivering exceptional customer service through real-time tracking, personalized delivery, and reliable carrier partnerships will be a key differentiator in a competitive market.

Harness AI’s Full Potential: By integrating composite and agentic AI, control towers can evolve from reactive monitors to active, self-correcting networks that drive efficiency and innovation.

Leverage Cutting-Edge Solutions: Innovators like Gocomet exemplify how advanced technology can elevate traditional control tower functions, ensuring organizations remain agile and future-ready.

As the global market continues to evolve, supply chain control towers will play an increasingly critical role in driving operational resilience and competitive advantage. Organizations that invest in advanced technologies—such as digital twins, AI-powered analytics, and integrated platforms like Gocomet—will be well-positioned to navigate the uncertainties of 2025 and beyond.

By embracing these trends and prioritizing proactive, customer-centric strategies, businesses can transform their supply chains into agile, data-driven powerhouses that not only withstand disruptions but also drive sustainable growth. The future is bright for supply chain control towers, and the leaders of tomorrow will be those who innovate, adapt, and harness technology to create resilient, efficient, and forward-thinking supply networks.