Top 3 Pain Points Caused By Lack Of Supply Chain Visibility – GoComet

According to a recent study, 69% of companies do not have total supply chain visibility.

Shippers face a daunting array of complicated difficulties or pain points when operating in today’s frequently volatile logistics and supply chain ecosystem. There are numerous potential sources of discomfort, but lack of visibility is the worst. So how can shippers gain the power to ensure visibility and reliability in end-to-end logistics?

But first, let’s understand why is supply chain visibility important.

- It’s the ability to track goods, components, and products, as they make their way from origin to the destination.

- It provides knowledge at the right time to leverage desirable actions.

- Greater visibility means greater overall operational efficiency and enhanced cost savings.

Now coming to the three major pain points due to poor supply chain visibility.

1) Challenge of customer satisfaction

The customer is the kingpin of any business; an unhappy customer means a high churn rate which ultimately means a loss in business. Due to the competitive delivery systems introduced by companies like Amazon, customers across sectors have high expectations for knowing the real-time status of their orders, which applies to business as well. Today, one of the vital parameters to gauge the services of a company is through the proactive communication received from the company when it comes to its logistics and delivery.

It’s definitely a plus if a shipper can offer unparalleled transparency and visibility to their customers – after all, customer satisfaction is key. With the right supply chain visibility software in place, companies gain access to a wealth of data. This allows them to develop more product-centric information, which can significantly enhance various aspects of operations, from planning and cost reduction to overall efficiency improvements.

2) Port congestion equals costly delays

The whole marine logistics has been continuously plagued with port congestion, and especially the situation has worsened since the first outbreak of the COVID pandemic. The global crises which followed one after the other have only made port congestion a pressing problem to supply chain leaders. These delays always translate into a loss of dollars.

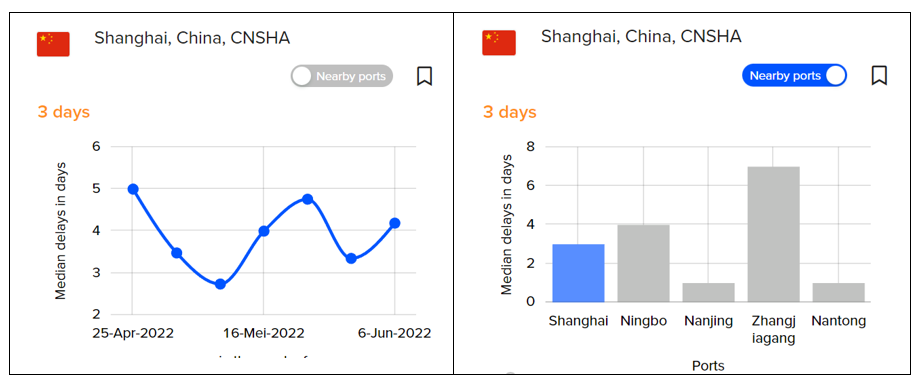

Having even basic information on real-time global port congestion could help plan critical shipments way better. For instance, knowing the median delays across major global ports can help proactively assess uncertainties and decide on an alternate course of action, which would significantly impact the cost.

You can access our Port congestion tool for free.

3) Incurring additional costs

Supply chain uncertainties are plenty in today’s political and volatile economic scenario. Geopolitical tensions, pandemic outbreaks, changing trade policies, and weather disruptions have added to the woes of an already stressed supply chain. As a shipper, having zero visibility and control over your shipments owing to these factors could be really frustrating. Because such inefficiencies often result in you incurring additional costs.

Ensuring clear visibility of the supply chain can save you from incurring additional costs such as detention and demurrage charges or other operational charges like fees for lost or compromised shipments. Also, with the ability to gain real-time insights, you can make informed business decisions well in advance to avoid paying those extra dollars.

Also Read: Three proven ways to avoid container demurrage and detention charges.

Feel free to reach out to us if you have been experiencing any of these challenges because of manual shipment tracking and a lack of real-time visibility and updates.