Supply Chain Cost Reduction: Top 10 Effective Strategies

Supply chain cost reduction is a top priority for businesses, especially those handling large volumes of shipments. Whether it’s freight procurement, logistics, or inventory management, every stage of the supply chain presents opportunities for optimization. This blog outlines ten actionable strategies to help businesses achieve significant cost reductions while maintaining operational excellence.

Type of Supply Chain Management Costs

These costs can be categorized into distinct areas. Supply chain cost reduction means careful management to maintain efficiency and profitability. Here’s a closer breakdown:

1. Transportation Costs: Transportation costs include freight charges, fuel expenses, and transit-related fees like demurrage or detention. Inefficient routes, vehicle downtime, or underutilized capacity can lead to inflated costs. Planning optimized routes and reducing idle time is critical to managing these expenses.

2. Inventory Costs: Inventory-related costs arise from holding, storing, and maintaining stock. Key elements include storage fees, insurance, and the risk of product obsolescence. Excess inventory ties up capital and increases risks, while insufficient stock can lead to missed opportunities or disruptions. Accurate demand forecasting helps balance these challenges effectively.

3. Procurement Costs: Procurement costs encompass sourcing, purchasing, and supplier management. These costs are influenced by administrative expenses, vendor negotiations, and quality assurance processes. Streamlining procurement activities and negotiating long-term contracts can reduce overall costs while improving supply chain reliability.

4. Operational Costs: Operational costs cover labor, energy, equipment maintenance, and technology systems. Manual processes and outdated systems often contribute to inefficiencies. Transitioning to efficient workflows and monitoring the usage of resources can significantly reduce these expenses.

5. Compliance Costs: Compliance costs arise from adhering to regulatory standards, including customs requirements, safety guidelines, and environmental protocols. Failure to comply can result in fines and delays while maintaining compliance requires investments in documentation, audits, and system checks.

Each cost category plays a vital role in the supply chain. Addressing inefficiencies in these areas ensures smoother operations and supports better supply chain cost reduction for businesses.

Supply Chain Cost Reduction Methods

Supply chain cost reduction is essential for maximizing profitability and operational efficiency. Below are ten actionable strategies to minimize costs while maintaining seamless operations.

1. Optimize Freight Management

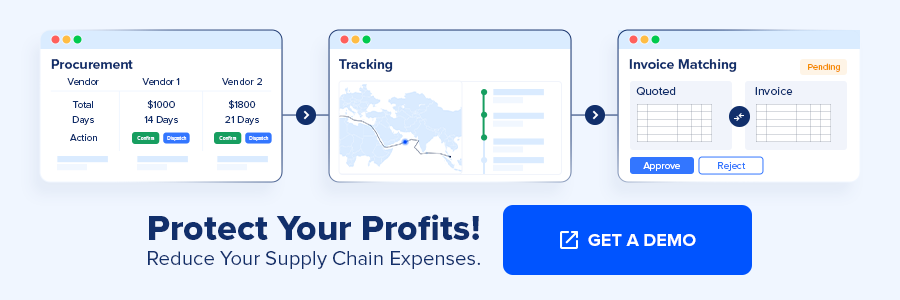

Freight management is one of the most significant cost centers in the supply chain. Businesses should negotiate carrier contracts based on shipment volume and delivery routes. Reviewing carrier performance periodically ensures services remain cost-effective and reliable. Poor carrier performance often leads to delays, penalties, and higher operational costs.

Incorporating freight consolidation can also yield substantial savings by maximizing container or truck space utilization. An efficient freight strategy ensures timely deliveries, reduces demurrage charges, and maintains customer satisfaction.

Transforming Freight Procurement:

A Case Study in Cost Savings

2. Implement Smarter Inventory Practices

Inventory costs often escalate due to overstocking, excess storage fees, and obsolete items. Shifting to just-in-time (JIT) inventory systems helps maintain optimal stock levels, preventing unnecessary expenses. Regular inventory audits can identify slow-moving items and free up working capital.

Additionally, leveraging demand forecasting improves order accuracy, ensuring that inventory aligns with sales patterns. A well-managed inventory system reduces carrying costs and minimizes stockouts, fostering operational efficiency.

3. Enhance Transportation Planning

Transportation costs, including fuel and freight charges, can be minimized with effective route planning. Optimizing delivery routes not only reduces mileage but also lowers fuel consumption. Businesses can also benefit from flexible transportation modes to suit shipment needs, such as rail for bulk goods and air for urgent deliveries.

Consolidating smaller shipments into larger loads ensures better utilization of vehicle capacity, reducing per-unit transportation costs. Proactive planning minimizes delays and enhances overall efficiency.

4. Streamline Invoice Management

Invoice errors can lead to overpayments and strained vendor relationships. Automating invoice reconciliation ensures that payments match contracted terms. Regularly auditing invoices for discrepancies avoids unnecessary expenses and identifies recurring issues for long-term resolution.

Faster, accurate invoice processing also shortens payment cycles, improving vendor relations and enabling negotiations for early payment discounts.

5. Strengthen Supplier Relationships

Collaborative supplier relationships lead to cost savings through negotiated discounts and better terms. Open communication fosters trust and ensures suppliers deliver high-quality materials on time, reducing delays and associated costs.

Regular supplier evaluations and efficient supplier relationship management ensure their performance aligns with business needs. Establishing strong partnerships encourages innovation, joint problem-solving, and long-term supply chain cost reduction.

6. Leverage Multi-Modal Logistics

Utilizing multiple transportation modes, such as combining road, rail, and sea; helps balance cost and delivery speed. For instance, sea freight is economical for long distances, while road transport is better suited for shorter hauls.

Choosing the right mix of transportation modes based on shipment needs ensures cost efficiency without compromising delivery schedules. Maintaining robust tracking mechanisms across all modes ensures operational transparency and positive supply chain cost reduction.

7. Invest in Employee Skill Development

Supply chain employees are critical to identifying inefficiencies and driving improvements. Providing training on cost-management strategies and logistics tools equips teams to make better decisions. Skilled employees can quickly adapt to new systems, minimizing downtime and improving productivity.

Encourage a culture of continuous learning where employees stay updated on industry trends and best practices, ensuring long-term organizational growth.

8. Adopt Lean Management Principles

Lean principles focus on eliminating waste across all stages for optimal supply chain cost reduction. This includes reducing unnecessary processes, excess inventory, and idle time. Streamlining workflows ensures every resource contributes to value creation.

Encourage teams to participate in identifying and removing inefficiencies. A lean approach not only lowers costs but also enhances overall responsiveness to market demands.

9. Monitor and Adjust KPIs Regularly

Key Performance Indicators (KPIs) like transportation cost per unit, order accuracy, and inventory turnover rate provide actionable data. Regularly monitoring these metrics highlights inefficiencies and areas for improvement.

Conduct quarterly performance reviews to assess the effectiveness of cost-reduction strategies. Adjusting tactics based on KPI insights ensures continuous improvement.

10. Explore Cost-Effective Sourcing

Global sourcing offers access to affordable materials, but it requires careful management of quality, lead times, and logistics. Evaluate the total landed cost, including tariffs and duties, to ensure actual savings.

Diversifying suppliers across regions mitigates risks and ensures supply chain stability. Regularly benchmark supplier pricing to stay competitive while maintaining quality standards.

Industry Report

Optimizing Freight Negotiation

For Cost Reduction 2024

The Benefits of Cost Effective Supply Chain Management

Implementing supply chain cost reduction strategies in supply chain management delivers measurable advantages, directly impacting profitability, operations, and customer satisfaction. Here’s a breakdown of the key benefits:

1. Improved Profit Margins

Effective supply chain cost reduction directly enhances profit margins by reducing unnecessary expenses. Savings achieved through streamlined procurement, optimized freight management, and lean inventory practices free up resources that can be reinvested in growth initiatives.

Supply chain cost reduction also provide businesses with a competitive edge, allowing them to offer more attractive pricing to customers or allocate funds to other strategic areas such as R&D or marketing.

2. Enhanced Efficiency

Supply chain cost reduction practices improve efficiency across all stages, from procurement to delivery. For instance, better route planning minimizes transit times, while automated workflows reduce labor-intensive tasks, enabling teams to focus on higher-value activities.

Efficiency also supports better decision-making, as real-time visibility and analytics allow businesses to anticipate and address bottlenecks before they escalate.

3. Greater Customer Satisfaction

Supply chain cost reduction ensures consistent, on-time deliveries, which builds trust and loyalty with customers. Cost-effective strategies like just-in-time inventory or multi-modal logistics help maintain service levels without inflating expenses.

Satisfied customers are more likely to remain loyal, generate repeat business, and recommend services, further enhancing revenue potential and brand reputation.

4. Scalability and Flexibility

A lean and optimized supply chain adapts more effectively to changing demands or market conditions. Cost-effective practices such as flexible sourcing and efficient inventory management ensure businesses can scale operations without proportionately increasing costs.

Scalable supply chains are better equipped to handle growth, seasonal demand spikes, or unforeseen disruptions like material shortages or transportation delays.

Supply chain cost reduction management is not just about cutting expenses; it’s about achieving a balance that supports operational excellence, customer satisfaction, and business growth. By consistently optimizing their supply chain processes, enterprises ensure long-term sustainability and maintain a competitive advantage.

Supply chain cost reduction management isn’t just about saving money; it’s about transforming how businesses operate. Companies can unlock efficiency, improve customer satisfaction, and drive sustainable growth by optimizing freight, inventory, procurement, and operational strategies.

Each strategy outlined here offers actionable steps to strengthen every stage of your supply chain. The goal isn’t merely to cut costs but to create a resilient, scalable, and competitive operation. Start small, measure progress, and embrace a mindset of continuous improvement, because a smarter supply chain leads to smarter business outcomes.