How is Predictive Freight Analytics Driving Smarter Supply Chains in 2025

Today, global supply chains are more interconnected and intricate than ever before. However, this complexity comes with challenges, including frequent delays, escalating costs, and inefficiencies that traditional freight management practices struggle to address.

As businesses aim to navigate these hurdles, the need for future-proof and resilient supply chains has never been more critical. Predictive freight analytics is emerging as a game-changer, helping organizations transform these challenges into opportunities for smarter decision-making and sustainable growth.

What is Predictive Freight Analytics?

Predictive freight analytics involves using advanced algorithms, machine learning, and real-time data to forecast freight outcomes such as potential delays, cost fluctuations, and optimal shipping routes. By integrating data from diverse sources—including historical shipment records, weather patterns, traffic conditions, and transportation systems—this technology provides actionable insights that optimize supply chain operations.

It’s not just about predicting the future but also enabling organizations to make proactive decisions that mitigate risks and enhance efficiency.

Key Benefits of Predictive Freight Analytics

Improved Decision-Making: Predictive analytics equips supply chain managers with actionable insights to make informed decisions. Real-time data combined with historical trends helps identify the best shipping routes, anticipate delays, and plan contingencies effectively.

Cost Optimization: By analyzing variables such as fuel prices, labor costs, and seasonal demand fluctuations, predictive freight analytics identifies opportunities to reduce costs while maintaining service quality.

Enhanced Efficiency and Time Savings: Automation powered by predictive insights streamlines operations, reduces manual intervention, and ensures timely deliveries. This efficiency translates into a competitive edge in a fast-paced market.

Risk Management and Mitigation: Predictive freight analytics identifies potential risks like weather disruptions, geopolitical conflicts, or port congestion. Businesses can prepare contingency plans to minimize the impact of such disruptions.

Potential 2025 Flashpoints Impacting Supply Chains

In 2025, the global supply chain faces mounting challenges, including labor disputes, geopolitical instability, and climate-driven disruptions. These flashpoints highlight the urgency for businesses to adopt predictive freight analytics as a proactive measure to mitigate risks and maintain seamless operations.

Port Strikes

Labor disputes remain a significant concern for global supply chains. For example, in October 2024, U.S. dockworkers and port employers engaged in a contentious labor strike that disrupted operations at major ports along the West Coast for several weeks.

This strike caused significant delays in freight movement, leading to backlogs and increased costs for businesses reliant on timely shipments. Although a tentative agreement was reached in January 2025, concerns persist about possibly a second strike later this year if negotiations over unresolved issues falter.

These incidents underscore the importance of predictive freight analytics in monitoring labor developments, forecasting potential disruptions, and enabling businesses to proactively adjust shipping schedules or explore alternative routes to maintain supply chain continuity.

US Presidency

Policy shifts play a significant role in shaping global trade dynamics. For instance, the administration’s potential implementation of a 25% tariff on goods from Mexico and Canada and a 60% tariff on Chinese imports, has already begun to impact industries ranging from automotive to pharmaceuticals.

These measures, reminiscent of the 2018 trade policies, have driven up costs for essential goods and heightened the need for businesses to adopt predictive freight analytics. By analyzing trade policy changes and modeling their effects, businesses can adjust sourcing strategies, identify alternative suppliers, and optimize freight planning to mitigate financial impacts.

Climate Change

Extreme weather events, such as the devastating California wildfires, cause unpredictable supply chain delays. These wildfires have disrupted key transportation networks, including road closures and damaged infrastructure, significantly delaying freight movement.

Predictive freight analytics enables businesses to anticipate and mitigate these challenges by analyzing weather forecasts, real-time traffic data, and historical patterns. For example, companies can proactively reroute shipments, adjust delivery timelines, and maintain open communication with stakeholders to minimize the impact of such disruptions on operations.

Red Sea

The Red Sea remains a critical shipping lane vulnerable to geopolitical tensions and regional instability. Recent escalations in conflicts along its coasts have disrupted cargo traffic, affecting global supply chains. The strategic significance of this region, connecting Europe to Asia, amplifies the risks of delays and increased shipping costs.

Predictive freight analytics offers vital tools for businesses to navigate these challenges by assessing geopolitical risks, simulating alternative shipping scenarios, and optimizing inventory management strategies to maintain operational continuity.

Tools and Technologies Empowering Predictive Freight Analytics

To harness the power of predictive freight analytics, businesses need to adopt cutting-edge tools and technologies. Here’s a checklist of essential components to look for:

AI and Machine Learning: These core technologies drive accurate forecasting by analyzing historical data, identifying patterns, and providing real-time insights. Machine learning models continuously improve over time, enabling more precise predictions and adaptive decision-making.

IoT Sensors: IoT devices enable real-time tracking of shipments, providing data on location, temperature, humidity, and other conditions during transit. This ensures better monitoring and immediate response to potential issues, such as deviations in optimal conditions.

Cloud Computing: Cloud platforms provide the infrastructure for seamless data integration across global supply chains. They enable companies to store, access, and analyze large datasets in real time, facilitating collaboration among stakeholders.

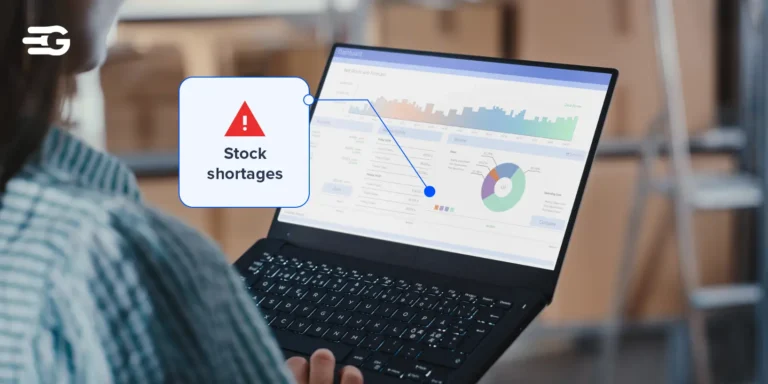

Data Analytics Platforms: These platforms centralize and analyze complex datasets to deliver actionable insights. They allow businesses to identify inefficiencies, predict bottlenecks, and streamline logistics processes to optimize overall performance.

Blockchain: Blockchain ensures data integrity and transparency by creating a decentralized and immutable ledger. This technology facilitates secure and seamless information sharing among stakeholders, reducing the risk of data tampering and enhancing trust. Additionally, blockchain supports smart contracts, automating processes like payment releases and compliance verification.

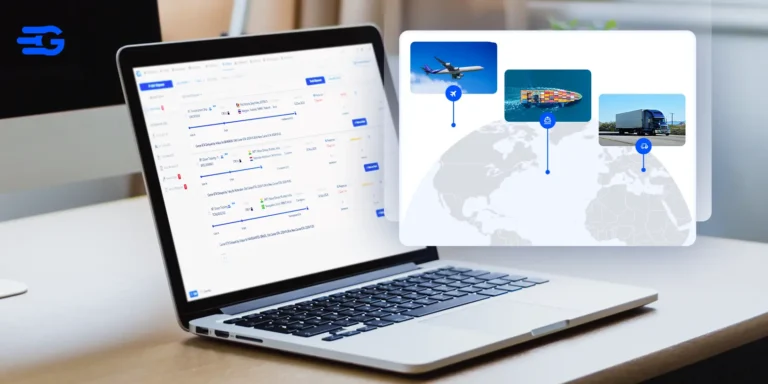

GoComet: Leveraging Predictive Freight Analytics for Smarter Supply Chains

GoComet’s advanced predictive freight analytics platform empowers businesses to build resilient supply chains by providing accurate, real-time insights. During the Red Sea crisis—where geopolitical tensions disrupted a key maritime route responsible for 12% of global trade and 30% of container traffic—GoComet played a pivotal role in mitigating the impact.

The platform’s predictive capabilities enabled businesses to reroute shipments efficiently, anticipate delays, and manage costs effectively. Leveraging multi-source data integration and AI-driven tools, GoComet provided:

This comprehensive approach allowed companies to stay agile, ensuring business continuity and minimizing disruptions.

In an era of increasing complexities, adopting predictive freight analytics is no longer optional—it’s essential for staying competitive. By leveraging these technologies, businesses can navigate disruptions, optimize costs, and enhance efficiency to thrive in 2025 and beyond.

To learn more about how GoComet’s solutions can empower your supply chain, visit our platform and discover the future of freight analytics today.