Supply Chain Risk Management Solutions: Strategies & Tools for Resilience

Table of Contents

Supply chains are more complex than ever. Disruptions can come from natural disasters, geopolitical tensions, supplier failures, or cyber threats. Without a solid risk management strategy, businesses face costly delays and operational setbacks. This is where Supply Chain Risk Management Solutions become essential.

What Is Supply Chain Risk Management?

Supply Chain Risk Management (SCRM) involves identifying, assessing, and mitigating risks that could disrupt the flow of goods and services. Effective SCRM helps businesses prevent delays, control costs, and maintain customer trust. Without a structured approach, even minor disruptions can lead to significant financial losses and operational setbacks.

Why Is It Essential for Modern Businesses?

Supply chain disruptions are increasingly common and costly. A survey by Statista revealed that such disruptions cost organizations worldwide an average of $184 million annually, with U.S. companies facing even higher average losses of $228 million per year.

These disruptions can result from various factors, including port congestion, extreme weather events, political instability, and supplier failures. Such events can lead to inventory shortages, increased freight costs, and delayed deliveries, directly impacting a company’s bottom line.

To effectively manage these risks, businesses must adopt proactive strategies. Implementing real-time tracking systems and predictive analytics enables companies to anticipate potential issues, optimize inventory levels, and respond swiftly to unforeseen events. This proactive approach not only safeguards profitability but also enhances overall supply chain resilience.

Key Challenges in Global Supply Chains

Global supply chains are the lifelines of international commerce, enabling the seamless movement of goods across borders. However, they face several critical challenges that can disrupt operations and impact businesses worldwide.

- Lack of Real-Time Visibility

Achieving comprehensive real-time visibility remains a significant hurdle for many organizations. A 2024 survey by The Conference Board revealed that 85% of executives from large companies are planning significant supply chain changes due to concerns about trade conflicts and the need for enhanced resilience. This underscores the urgency for improved monitoring and transparency. - Supplier Reliability Issues

Dependence on a diverse network of suppliers exposes companies to potential disruptions. In 2024, supply chain vulnerabilities were highlighted by a significant port strike on the U.S. East and Gulf Coasts, which threatened to disrupt billions of dollars in goods, particularly in sectors like apparel and footwear. This event emphasized the fragility of supplier networks and the need for robust contingency plans. - Regulatory Compliance Complexities

Navigating the intricate web of international trade regulations adds layers of complexity to supply chain management. The implementation of new trade policies and tariffs has compelled companies to reevaluate and strengthen their supply chains to mitigate risks associated with geopolitical tensions. For instance, the re-elected President of USA, Donald Trump is ensuing trade wars prompted many global companies to plan significant supply chain adjustments. - Cybersecurity Threats:

The digitalization of supply chains has heightened exposure to cyber threats. A 2024 report highlighted that 54% of large organizations identified supply chain vulnerabilities as the primary barrier to cyber resilience. This underscores the critical need for robust cybersecurity measures to protect against data breaches and operational disruptions.

Addressing these challenges requires a proactive approach, including investing in advanced technologies, diversifying supplier bases, staying abreast of regulatory changes, and implementing stringent cybersecurity protocols to build a resilient and agile supply chain.

Managing Supply Chain Risks with AI-Powered Visibility

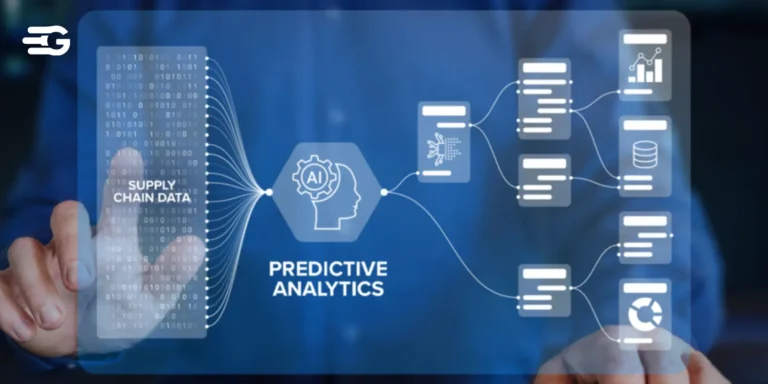

Supply chain disruptions can lead to delays, financial losses, and operational inefficiencies. Businesses relying on manual tracking and reactive problem-solving often struggle to respond quickly to unexpected issues. This is where AI-powered visibility makes a difference.

As Gautam Prem Jain, Co-founder of GoComet, explains:

“AI-powered visibility is transforming supply chain risk management. Companies no longer have to rely on manual tracking or guesswork. Real-time data and predictive analytics help them anticipate delays, optimize inventory, and mitigate risks before they escalate.”

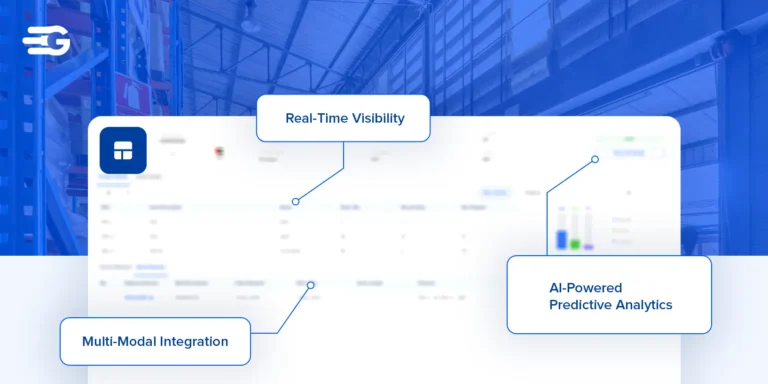

With real-time tracking, predictive analytics, and automated risk assessment, companies can identify potential disruptions early, adjust logistics strategies, and ensure smoother operations. GoComet’s AI-driven platform helps businesses stay ahead of risks by providing actionable insights, reducing inefficiencies, and improving overall supply chain resilience.

5 Must-Have Tools for Supply Chain Risk Management

Managing supply chain risks requires businesses to be proactive and equipped with the right tools. Delays, supplier failures, and regulatory changes can disrupt operations and cause financial losses. Here are five essential solutions that help mitigate risks effectively:

- AI-Powered Supply Chain Risk Software

Advanced risk management platforms, such as our supply chain risk management solution, use AI-driven predictive analytics to identify potential disruptions before they happen. These platforms analyze historical data, weather patterns, geopolitical events, and shipment trends to help businesses minimize delays and optimize logistics. - Real-Time Tracking Tools

Lack of end-to-end visibility is a major challenge in supply chains. Solutions like GoTrack provide real-time shipment tracking, reducing uncertainty and enabling faster decision-making. Businesses can identify delays, reroute shipments, and enhance customer satisfaction by leveraging GPS, IoT, and automated alerts. - Supplier Risk Assessment Systems

Supplier reliability is a key factor in avoiding unexpected disruptions. A supplier risk assessment system evaluates vendors based on past performance, financial stability, and compliance records. Companies using such tools can proactively switch to backup suppliers and strengthen supply chain resilience. - Automated Compliance Management

Trade policies, tariffs, and regulatory requirements change frequently. Automated compliance management tools ensure businesses stay updated with international trade laws and avoid penalties. These systems automate documentation, customs filings, and risk assessments, reducing compliance-related bottlenecks. - Data Analytics & AI-Based Forecasting

Predicting risks before they escalate is crucial. AI-driven data analytics tools analyze market conditions, demand fluctuations, and logistics trends to identify potential disruptions. Companies using predictive analytics can adjust sourcing strategies, manage inventory efficiently, and mitigate financial risks.

Best Practices for Managing Supply Chain Risk

Supply chain disruptions can result in delays, financial losses, and reputational damage. To minimize risks and ensure business continuity, companies must adopt proactive strategies. Here are five best practices to strengthen supply chain resilience:

- Enhance Real-Time Visibility

A lack of transparency can lead to delays and missed opportunities for risk mitigation. AI-powered tracking solutions like GoTrack provide real-time shipment visibility, enabling businesses to monitor cargo movement, detect bottlenecks, and make data-driven decisions to prevent disruptions. - Diversify Suppliers

Relying on a single supplier or region increases vulnerability to unexpected failures, geopolitical tensions, or natural disasters. Businesses should establish relationships with multiple vendors across different locations to ensure continuous supply and mitigate risks from supplier failures. - Leverage Risk Assessment Tools

Regular evaluation of suppliers and logistics partners is essential for identifying potential vulnerabilities before they impact operations. Supplier risk assessment systems analyze financial stability, past performance, compliance records, and geopolitical risks to help businesses make informed decisions and strengthen partnerships. - Strengthen Cybersecurity

As digital transformation accelerates, cyber threats targeting supply chains have increased. Companies should implement robust cybersecurity measures such as data encryption, multi-factor authentication, and real-time threat monitoring to protect sensitive data from cyberattacks and prevent operational disruptions. - Develop Contingency Plans

Unforeseen events like port congestion, regulatory changes, or transportation failures can disrupt supply chains. Businesses should prepare by mapping alternative routes, securing backup suppliers, and establishing emergency action plans to maintain supply chain continuity during crises.

FAQs

How Can AI Help in Identifying and Reducing Risks?

AI-driven supply chain risk software analyzes historical data, predicts potential disruptions, and suggests proactive solutions. It helps businesses minimize risks before they cause major disruptions.

Why Is Real-Time Visibility Crucial for Supply Chain Risk Management?

Without real-time data, businesses operate blindly, leading to delays and inefficiencies. Tools like GoTrack provide end-to-end shipment visibility, ensuring better decision-making and faster response to disruptions.