The Ultimate Guide to Supply Chain Technology: Innovations & Best Practices

Table of Contents

Supply chain technology has come a long way from spreadsheets and manual tracking. Today, businesses rely on AI, automation, and real-time data to stay ahead. But what exactly is supply chain technology, and why does it matter now more than ever?

In this guide, we’ll break it down: what it is, why it’s essential, and how it’s transforming businesses worldwide. Plus, we’ll explore the best practices for implementing these technologies and how GoComet is leading the charge.

What is Supply Chain Technology?

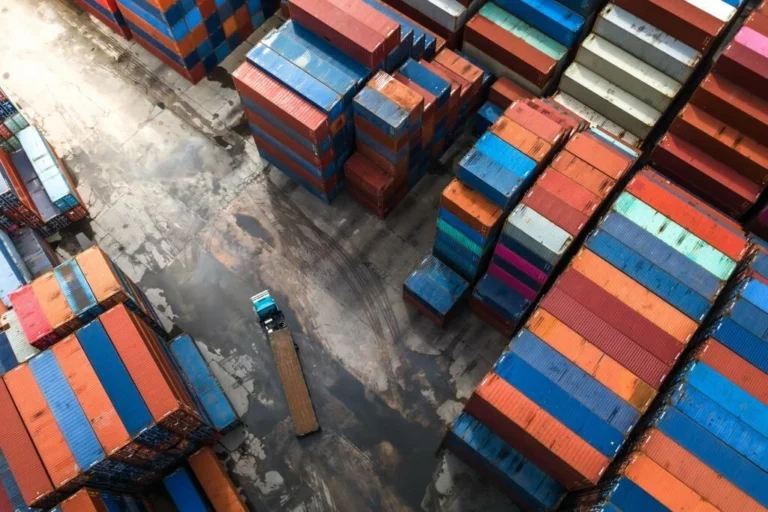

Supply chain technology refers to the tools, software, and systems that help businesses. Think of supply chain technology as the brains and muscles behind smooth logistics. It includes tools, software, and systems that help businesses manage shipping, procurement, and inventory with less hassle and more efficiency. AI, automation, cloud computing, IoT, and blockchain are some of the key players making this happen.

Why Supply Chain Technology Matters in 2025 and Beyond

Supply chains are getting more complex, and disruptions are hard to predict. The right tech keeps businesses resilient, visible, and ready for anything, whether it’s fluctuating demand, geopolitical tensions, or climate-related challenges.

Benefits of Supply Chain Technology for Businesses

Staying ahead isn’t just an advantage, it’s a necessity. The right tech speeds up operations, improves accuracy, and cuts costs. Here’s how businesses are benefiting.

Enhanced Visibility & Real-Time Data Insights

Wouldn’t it be great to see problems before they happen? Modern platforms provide real-time tracking, predictive analytics, and AI-powered forecasting, keeping businesses one step ahead with end-to-end visibility.

Improved Supply Chain Efficiency & Cost Savings

Automation and AI eliminate bottlenecks and reduce costs. Companies using tech-driven solutions cut transport expenses and streamline warehouses, making operations smoother and more profitable.

Faster and More Accurate Decision-Making

AI and big data remove the guesswork from supply chains. Businesses get real-time insights for smarter decisions on inventory, routes, and suppliers.

Risk Management & Business Continuity Planning

Predictive analytics, blockchain for transparency, and AI-powered risk assessments help companies identify threats early and create backup plans to avoid disruptions.

Core Technologies Transforming Supply Chains

Technology is revolutionizing supply chains, making them faster, smarter, and more reliable. Let’s break down the key innovations in the supply chain driving this shift.

The Role of AI and Machine Learning in Supply Chains

AI solves problems fast. It predicts demand, automates tasks, and fine-tunes supply chains using real-time data. Businesses get faster deliveries, lower costs, and fewer disruptions.

Automation & Robotics

Robots don’t take breaks. They pick, pack, and sort goods in warehouses at record speed. Self-driving trucks and automated forklifts move shipments without delays. Fewer mistakes, faster deliveries.

Cloud Computing

With cloud-based systems, businesses can track shipments, manage orders, and access data from anywhere. It’s secure, scalable, and keeps everyone on the same page.

IoT & Blockchain

IoT sensors track shipments live, no more guessing. Blockchain locks in data, making transactions secure and tamper-proof. That means less fraud, fewer errors, and more trust.

Big Data & Predictive Analytics

Data makes the difference. AI crunches numbers to predict demand, optimize delivery routes, and avoid costly delays. The result? Faster shipments, lower costs, and happy customers.

How AI Is Revolutionizing Supply Chain Technology

AI is transforming supply chains, making them faster, smarter, and more cost-efficient. Companies like Essentra have leveraged AI-driven solutions to reduce costs, improve efficiency, and gain a competitive edge.

AI-Powered Demand Forecasting & Inventory Optimization

AI analyzes market trends, historical data, and real-time demand to help businesses prevent stockouts and reduce excess inventory. With predictive insights, companies can optimize supply levels, ensuring smooth operations.

Intelligent Automation: Reducing Human Error & Manual Effort

AI automates procurement, shipment tracking, and invoice management, cutting down on manual work and minimizing errors. Essentra’s adoption of our AI-powered tools reduced invoice processing time, improved vendor communication, and eliminated overpayments, saving over 20 hours per month on invoice reconciliation.

How AI is Driving Supply Chain Success

Companies like Essentra have used AI to optimize freight selection, enhance real-time tracking, and secure better vendor deals, saving over 4.34% on freight spend. AI-driven dashboards provide valuable data insights, ensuring better decision-making and efficiency gains.

AI is already here and it is continuously transforming supply chains for businesses worldwide.

Best Practices for Implementing Supply Chain Technology

Technology can transform your supply chain, but only if it’s implemented correctly. A rushed rollout leads to wasted time, frustrated employees, and poor results. Here’s how to do it right.

Choosing the Right Technology

Not all supply chain tech is a good fit. Start by identifying weak spots. Are shipments delayed? Are inventory levels inaccurate? Do costs keep rising? Find solutions that address these pain points. Look for systems that integrate easily with your existing software and can scale as your business grows. Cloud-based and AI-driven tools offer flexibility and real-time insights, making them strong choices.

Avoiding Common Pitfalls

Tech adoption fails when businesses focus only on the tools, not the people using them. Employees need proper training and time to adjust. Resistance to change is normal, so leadership must communicate the benefits clearly. System integration is another hurdle. If new software doesn’t connect well with current platforms, it creates more problems than it solves. Work with IT teams to ensure seamless data flow between old and new systems.

Measuring ROI

If you can’t measure it, you can’t improve it. Track key metrics like cost savings, efficiency gains, delivery speeds, and error reduction. Compare pre- and post-implementation data to see the real impact. If improvements aren’t happening, adjust workflows or provide additional training. AI and analytics tools can help identify bottlenecks and fine-tune performance over time.

A successful tech rollout isn’t just about upgrading the system. It’s about upgrading how your business operates. The right strategy ensures long-term success, keeps teams productive, and maximizes ROI.

Future Trends in Supply Chain Technology

Supply chains are getting smarter, greener, and more automated. Here’s what’s next.

Digital Twins: Test Before You Act

Want to know if a new strategy will work before making changes? Digital twins make it possible. They create virtual versions of supply chain operations, helping businesses spot problems, test solutions, and improve efficiency without real-world risks.

Sustainable Supply Chains: Cutting Waste and Costs

More companies are tracking carbon emissions, optimizing shipping routes, and using eco-friendly packaging. AI helps prevent waste by predicting demand more accurately. Going green isn’t just good for the planet. It saves money and keeps businesses compliant with new regulations.

Supply chain tech isn’t a choice anymore. It’s how businesses stay ahead, cut costs, and avoid disruptions. Those who adapt now won’t just keep up, they’ll lead.

Wrapping up

AI is redefining supply chains with faster deliveries, lower costs, and smarter decision-making. Companies like Essentra are already seeing the impact, using AI to boost efficiency and stay ahead in a competitive market. As technology evolves, businesses that embrace AI will continue to lead the way.st efficiency and stay ahead in a competitive market. As technology evolves, businesses that embrace AI will continue to lead the way.