The Intricate Logistics of Formula 1

Formula 1 (F1) is not just a racing spectacle; it’s a symphony of speed, precision, and technological prowess. Behind the high-octane races and state-of-the-art engineering lies a meticulously orchestrated supply chain that propels the sport to global heights. This article uncovers the intricate logistics of F1, highlighting how logistical excellence drives the sport forward while also spurring advancements in broader supply chain practices.

The Global Stage of F1 Logistics

Since its inception in 1950, F1 has transformed from a European pastime into a worldwide phenomenon, captivating millions with its thrilling races across multiple continents. Each season, the F1 circus embarks on a relentless journey, visiting over 20 countries with vastly different logistical landscapes. From the sun-drenched circuits of Australia to the legendary streets of Monaco, the sport’s global reach demands an unparalleled level of supply chain coordination and execution.

The F1 Industry: Economic Impact and Logistics

The global Formula 1 industry is valued at approximately $2 billion annually, encompassing revenue from race hosting fees, broadcasting rights, sponsorships, and merchandise sales. Including the importing and exporting of car parts, assembly kits, and other essential equipment, logistics accounts for an estimated 10-20% of the total F1 industry expenditure, translating to roughly $200 million to $400 million annually dedicated to logistics operations.

Orchestrating the F1 Supply Chain

The relentless pace of the F1 calendar, with races nearly every other weekend, necessitates a finely tuned logistical operation. Each team is a self-contained unit, transporting up to 50 tons of equipment – including race cars, spare parts, and garage infrastructure – to every Grand Prix. This colossal endeavor involves a complex interplay of air, sea, and land transportation, requiring meticulous planning and execution.

Consider the Monaco Grand Prix, a logistical puzzle unlike any other. The principality’s narrow streets and limited space create extraordinary challenges. Teams must meticulously plan and execute their operations within this confined environment, showcasing the pinnacle of supply chain adaptability.

Shipping Distances and Methods

F1 teams travel across five continents, covering an estimated 100,000 kilometers during a season. Key locations include Europe, Asia, North and South America, and the Middle East.

Shipping Methods:

- Air Freight: The primary method due to the speed and reliability required. Cargo planes specifically chartered for F1 logistics ensure timely delivery. For example, teams use Boeing 747 and Antonov An-124 aircraft to transport cars and equipment.

- Sea Freight: Used for less critical items to reduce costs. Sea freight shipments are planned well in advance to align with the race calendar. For instance, large ships carrying non-essential equipment set sail months before the season starts.

Sourcing of F1 Vehicle Parts

Global Sourcing:

- Engine Manufacturing: Engines are produced by specialized manufacturers like Mercedes-AMG (Germany), Ferrari (Italy), Renault (France), and Honda (Japan).

- Chassis and Body: Constructed primarily in the UK (McLaren, Williams, Aston Martin), Italy (Ferrari, AlphaTauri), and Germany (Mercedes-AMG) using carbon fiber composites.

- Other Components: High-tech parts like electronics, aerodynamics components, and tires are sourced from various suppliers worldwide, including the UK, Italy, and the USA.

Special Containers for F1 Vehicles

F1 teams use custom-made containers specifically designed to protect high-value and sensitive parts. These containers are often climate-controlled and reinforced to prevent damage.

Comparison to Regular Containers: Unlike standard shipping containers, F1 containers are tailored to the exact dimensions and requirements of the parts they carry, providing additional security and reducing the risk of damage during transit.

Examples of Use: For example, Red Bull Racing uses custom-built containers for their chassis, which include shock-absorbing materials and are designed to maintain a stable temperature to protect sensitive components.

Loading and Unloading Procedures

Loading Techniques: Containers are loaded using specialized equipment such as cranes and forklifts designed to handle delicate and high-value cargo. Teams have dedicated logistics staff trained in handling these procedures.

Unloading Procedures: At race venues, trained personnel carefully unload the containers, ensuring that each component is handled with precision to prevent damage and ensure readiness for assembly. For example, the paddock setup involves meticulous coordination to ensure all equipment is in place and functional.

Shipping Costs Per Race

Cost Breakdown:

- Air Freight: High costs due to speed and reliability; a single air freight shipment can cost upwards of $1 million per race. For example, the logistics cost for the Australian Grand Prix, considering the distance from Europe, can exceed this amount.

- Sea Freight: More cost-effective, but slower. Used for non-critical items. Costs vary but are generally a fraction of air freight expenses. For instance, shipping non-essential equipment by sea to Australia might cost around $200,000.

- Total Seasonal Costs: An F1 team’s logistics budget can range from $8 million to $20 million per season, depending on the number of races and the distances involved.

Real-Case Scenarios of Mishaps and Delays

Notable Incidents:

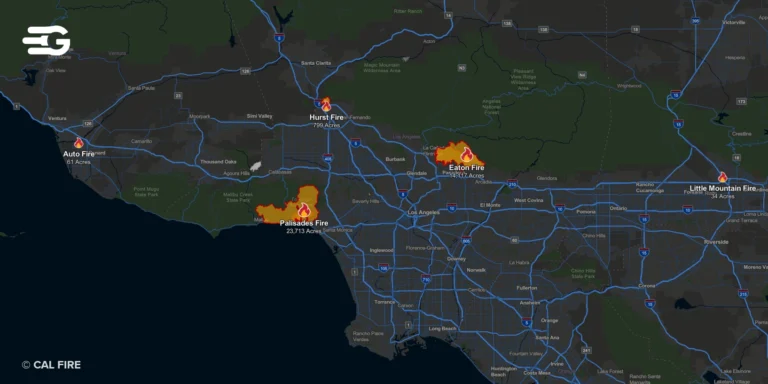

- Weather-Related Delays: In 2018, the Japanese Grand Prix faced significant delays due to Typhoon Hagibis, causing logistical challenges in transporting equipment to the race venue. The typhoon disrupted flight schedules, leading to delays in the arrival of essential components.

- Customs Issues: During the 2019 Brazilian Grand Prix, several teams experienced customs delays that led to late arrivals of crucial equipment. Customs clearance procedures were slower than expected, causing teams to scramble to get their gear in place before practice sessions.

- Accidental Damage: Instances where equipment has been damaged in transit, although rare, have occurred. In 2017, a Red Bull Racing car sustained minor damage during air transport due to turbulence. Teams use extensive padding and custom containers to minimize this risk.

Mitigation Strategies

Backup Equipment: Teams often send additional backup parts and equipment to mitigate the impact of any delays or damages. For example, McLaren routinely sends extra components to every race, ensuring they can quickly replace any damaged parts.

Flexible Scheduling: Close coordination with logistics partners ensures that potential delays are accounted for, and alternative plans are in place. This includes planning multiple shipping routes and having backup charter flights ready.

Technology and Coordination

Real-Time Tracking: Advanced tracking systems allow teams to monitor the location and status of their shipments in real time, enabling proactive management of any issues. For instance, Mercedes-AMG uses GPS tracking and IoT sensors to monitor their shipments continuously.

Dedicated Logistics Partners: Teams work with experienced logistics companies specializing in handling high-value and sensitive cargo, ensuring reliable and efficient transportation. DHL, the official logistics partner for Formula 1, provides specialized services tailored to the needs of the teams.

Precision, Speed, and Inventory Mastery

In F1, success is measured in milliseconds, making precision and timing crucial. Teams must have the right parts in the right place at the exact moment, demanding a level of inventory management that borders on the obsessive. From tires and engines to the smallest components, F1 teams maintain extensive stockpiles to mitigate unexpected challenges and optimize performance.

Mercedes-AMG Petronas, a dominant force in F1, exemplifies the power of advanced inventory management. Their sophisticated systems and real-time data tracking enable them to strike the perfect balance between having the necessary components on hand and avoiding unnecessary costs.

Technological Innovation: Fueling the Supply Chain

F1 has always been a breeding ground for technological advancements, and the supply chain is no exception. Teams harness the power of real-time tracking, predictive analytics, and artificial intelligence to optimize their logistics operations. The vast amounts of data generated during races and testing provide invaluable insights for improving efficiency and reducing costs.

Moreover, F1 teams are at the forefront of adopting emerging technologies like 3D printing. This revolutionary process enables rapid production of replacement parts, reducing lead times and enhancing flexibility.

Partnerships for Success

Collaborations with specialized logistics providers like DHL are essential for F1 teams. These partnerships offer tailored solutions, leveraging industry expertise to overcome the unique challenges of the sport. Additionally, sponsors often contribute logistical resources, creating a synergistic ecosystem that drives performance.

Overcoming Challenges: The F1 Way

The high-stakes world of F1 is fraught with challenges. Tight schedules, diverse regulatory environments, and the constant threat of unforeseen circumstances demand robust risk management strategies. Teams must be prepared for anything, from customs delays to equipment failures, to ensure the show goes on.

Sustainability: A New Lap

While F1 has traditionally been associated with a significant environmental footprint, the industry is increasingly focused on sustainability. Teams and organizers are adopting eco-friendly practices, such as carbon offsetting and the use of renewable energy, to reduce their impact. The future of F1 logistics promises to be even greener, with a focus on efficient transportation and sustainable supply chain technologies.

Beyond the Track: Impact on the Supply Chain Industry

The lessons learned in the high-pressure environment of F1 have far-reaching implications for the broader supply chain industry. Advancements in inventory management, real-time tracking, and data analytics, driven by the sport’s demands, are being adopted by businesses across sectors. Additionally, F1’s emphasis on global operations and complex regulatory landscapes offers valuable insights for companies navigating international trade.

Formula 1 is all about precision, speed, and seamless logistics. Behind the scenes, the sport relies on an intricate supply chain to move cars, parts, and teams across the globe without delays. The high standards of F1 logistics push for constant innovation, setting an example for industries worldwide.

GoComet’s supply chain solutions can play a vital role in this fast-paced environment. With real-time tracking and predictive analytics, GoComet helps ensure timely deliveries and smooth operations, perfectly aligning with the high demands of Supply Chain logistics – see how we can help you optimise!