Sustainable Supply Chains: The Role of Automation in Reducing Carbon Footprint

Every supply chain leaves a mark. Not just on profits or performance, but on the planet. While businesses scale, emissions climb quietly in the background through inefficient transport, energy-heavy warehouses, and overproduction no one tracks in real-time. The systems built to move goods fast are now slowing down the race toward sustainability.

But what if the fix isn’t manual change or policy pressure? What if it’s automation, done right? This piece breaks down how smart systems are reshaping old supply chains into clean, efficient, sustainable supply chains. And a shift that’s already happening. Let’s dive in.

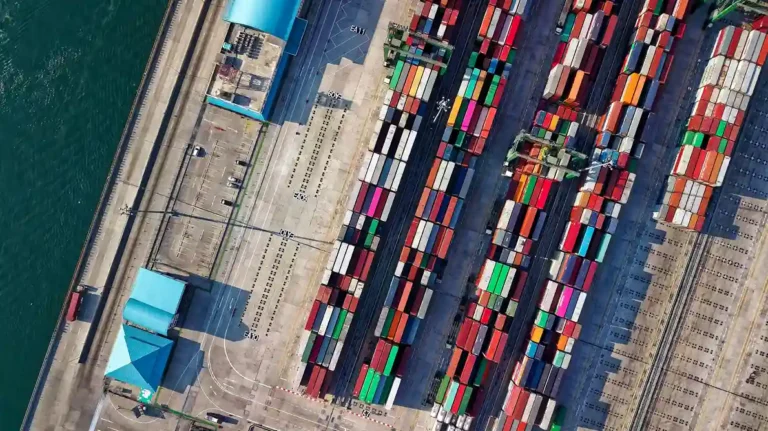

The Environmental Impact of Traditional Supply Chains

Traditional supply chains were never built with sustainability in mind. Most of them evolved for speed, cost-cutting, and scale, but not environmental responsibility. This has led to a system that leaks carbon at almost every layer.

- Inefficient routing in logistics: Trucks running half-empty, poorly optimized delivery paths, or unnecessary detours: all of it stretches fuel consumption way beyond what’s needed. According to the International Transport Forum, freight transport alone accounts for about 30% of global transport-related CO2 emissions.

- Energy wastage in warehouses and production units: Lighting and HVAC systems run nonstop, even during low-activity periods. Manual sorting, outdated machinery, and zero visibility into energy patterns lead to consistent overuse of electricity.

- Manual processes across the board: Slow, human-driven tasks mean longer processing times, more idle machinery, and a reactive maintenance culture. These inefficiencies scale up fast in complex supply chains.

- Overproduction and poor inventory management: When forecasting misses the mark, businesses produce more than needed. That excess needs to be stored, cooled, transported, or eventually discarded. And each of those steps carries a heavy carbon tag.

So when we talk about sustainable supply chains, the first step is acknowledging how broken the legacy systems are. The traditional model is fragmented. It works in silos. And that fragmentation keeps emissions high, because no one has the full picture.

Until that picture becomes clearer, and smarter traditional supply chains will keep being a drag on sustainability goals.

The Role of Automation in Sustainability

In supply chain management, automation means using technology to handle repetitive tasks. Things like inventory checks, shipment scheduling, route planning, maintenance alerts, and warehouse coordination.

But the real value lies in how these systems reduce waste and save energy. And here’s how automation supports sustainability in action:

| Automation Focus | What It Does | Sustainability Impact |

| Process Optimization | Adjusts operations based on real-time conditions | Lowers fuel use and avoids energy overuse |

| Energy-Efficient Operations | Uses smart systems to control lighting, cooling, and machinery activity | Cuts electricity waste in warehouses and factories |

| Waste Reduction | Matches production to actual demand, reduces defects | Prevents overproduction and limits storage-based emissions |

| Automated Transportation | Plans the most efficient delivery routes and schedules | Shrinks carbon output from freight and delivery |

| Predictive Maintenance | Detects problems early so machines are fixed before they fail | Reduces energy spikes and extends equipment life |

When these tools come together, the supply chain becomes sharper and lighter. Every small fix adds up. Less waste. Fewer delays. Lower emissions.

The result is a system that runs cleaner without losing speed.

Key Benefits of Automating Supply Chains for Sustainability

When the right systems are in place, efficiency and environmental impact aren’t two different goals. They move together.

- Reduced Carbon Emissions

Most emissions in traditional supply chains come from transport, excess energy usage, and reactive planning. Automation flips that. With route optimization, real-time tracking, and intelligent scheduling, vehicles travel shorter, smarter paths. Machines run only when needed. There’s no overuse, no idle burn.

Even a 5 to 10 percent improvement in transport efficiency can lead to sharp drops in fuel consumption. That’s a direct hit on carbon output.

- Enhanced Operational Efficiency

Automation removes lag. Tasks that took hours now happen in minutes. Inventory gets updated in real-time. Orders sync instantly. Maintenance isn’t about waiting for breakdowns.

The system becomes faster, cleaner, and less error-prone. That efficiency reduces waste across departments. When operations flow smoother, there’s less energy wasted on catching up, correcting, or compensating. It keeps things lean.

- Resource Optimization

Human planning can’t match machine-level precision. Automated systems pull real data to adjust supply based on demand. This keeps raw material use in check and avoids overproduction.

In warehouses, smart shelving and picking systems reduce movement and energy. Lighting systems stay off in unused zones. Packaging units scale output based on live order volume. All this saves energy and cuts down on excess material use.

- Data-Driven Decision Making

Sustainability thrives on visibility. Automation brings that in through data. Sensors, trackers, and dashboards create a live feed of everything: fuel use, energy consumption, idle time, machine health, and more.

With this data, managers stop guessing. They start acting based on patterns. That leads to smarter decisions. Like shifting operations to off-peak hours when energy grids are cleaner. Or adjusting transport schedules to avoid fuel-heavy stop-start routes.

This level of insight can rewire the whole system to run better, cleaner, and more intentionally.

Platforms like GoComet bring this visibility to life. With features like real-time container tracking, predictive ETAs, and CO2 emissions monitoring, supply chain managers get not just data but decision-ready insights.

Real-Life Examples

Maersk, one of the largest container shipping companies in the world, has taken a data-first approach. By integrating AI into their fleet operations, they’ve been able to optimize vessel speed and routing based on real-time weather, fuel, and cargo data. The result is not just operational efficiency but a measurable cut in fuel usage, up to 10% in some routes. That directly translates into fewer emissions across one of the most emission-heavy segments of global trade.

Beluga Shipping approached the same problem from a different angle. Their vessels were equipped with the SkySails system, a computer-controlled kite that harnesses wind power to support propulsion. This hybrid automation setup helped cut diesel use by as much as 50% in favorable conditions, while consistently delivering a 10–35% reduction in carbon emissions. It’s a clear example of how mechanical automation and environmental strategy can work hand in hand.

Challenges and Considerations

Businesses already have legacy processes, tight budgets, and a stack of moving parts.

So while automation plays a massive role in building sustainable supply chains, there are roadblocks that can’t be ignored.

While there can be endless things stopping you, here are the 5 key challenges most companies face:

- High Initial Costs: Setting up automation isn’t cheap. Sensors, software, integration tools, system upgrades. It all adds up. For smaller players, the upfront investment can feel too steep, even if the long-term payoff is obvious.

- Integration with Legacy Systems: Many supply chains still run on outdated ERP setups or fragmented tools. Plugging automation into these older systems isn’t smooth. Compatibility issues, data sync problems, or even complete process rewrites might be needed.

- Skilled Workforce Gap: Tech is only useful when people know how to use it. But automation tools often need skilled operators, data analysts, or process engineers. That talent gap slows down rollout or leads to poor implementation.

- Cybersecurity and Data Risks: More automation means more data points. And more data means more exposure. Without proper security, automated systems become targets. A supply chain hack can wreck trust and leak sensitive info.

If you think about it, no solution is ever plug-and-play. But that doesn’t mean automation should be avoided. Start with high-impact, low-disruption areas. Pilot. Measure. Expand. Build buy-in from teams. Upskill slowly. And always keep security on the radar.

Future Trends in Sustainable Supply Chains

The future of sustainable supply chains is leaning harder into intelligence. Not just automation for the sake of speed, but smart systems that predict, adapt, and self-correct.

AI-powered analytics are starting to take over demand forecasting, energy load balancing, and route optimization. These tools learn from patterns and improve over time.

IoT is another big layer. With real-time sensors in trucks, warehouses, and factory lines, businesses get a live view of their environmental impact.

Add blockchain, and you’ve got transparent logs of emissions, sourcing, and movement. It won’t be about just compliance anymore. It’ll be about traceability. Knowing exactly where the carbon is coming from, and where to cut.

That shift, from reactive to proactive systems, is what’s going to define the next phase of sustainable supply chains.

Final Thoughts

Building sustainable supply chains isn’t a one-time fix. It’s a systems-level shift. Automation isn’t just a nice-to-have anymore. It’s the lever that turns complex, high-emission operations into streamlined, eco-conscious engines. From reducing waste to cutting fuel, the benefits stack fast when the right tools are in place.

But for that shift to work, visibility matters. You need to track what’s happening, where emissions are leaking, and how operations respond to change. That’s where tools like GoComet’s CO2 Tracker come in. It gives logistics teams the data they need to act smarter, not just faster.

If sustainability is on the roadmap, and it should be, then it starts with insight. Book a GoComet demo and see how automation meets accountability.