AI in Supply Chain Management: What Is It and How It Works?

The role of AI in supply chain management is nothing short of transformative. Today, AI is not just a buzzword; it’s reshaping how businesses manage their supply chains, making them more agile, efficient, and cost-effective. With AI, companies can optimize every aspect of their operations, from inventory management to predictive maintenance.

We will explore what AI in supply chain management is, how it works, and the advantages of using AI, especially generative AI, in enhancing supply chain operations. We’ll also delve into the key roles AI plays and how businesses can leverage its potential to drive operational efficiency.

What is AI in Supply Chain?

AI, or Artificial Intelligence, refers to the ability of machines and computer systems to perform tasks that traditionally require human intelligence. These tasks include things like analyzing data, making predictions, and even learning from experience.

In supply chain management, AI is used to optimize processes such as inventory control, route planning, demand forecasting, and supplier relationships. It helps businesses make smarter decisions by analyzing vast amounts of data quickly and providing insights that might be too complex for traditional systems to uncover.

AI in supply chain management is not limited to just data analysis. It can automate repetitive tasks, reduce human error, and streamline operations to create a more efficient and cost-effective supply chain. For instance, AI can predict demand based on various factors such as historical sales, seasonality, or even external data like social trends and weather patterns. This predictive capability significantly enhances the accuracy of supply chain planning.

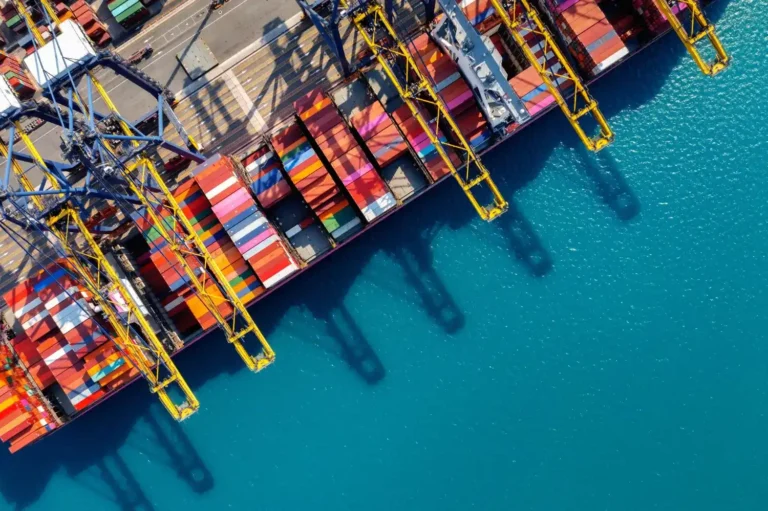

AI in supply chains also integrates with other technologies like IoT (Internet of Things) and cloud computing, enabling real-time monitoring and analysis. For example, AI can be used to track shipments in real-time, alerting businesses to potential delays and helping them adjust plans accordingly.

How Does AI in Supply Chain Work?

AI works by analyzing massive amounts of data and using algorithms to identify patterns, make predictions, and optimize decisions. Here’s how it generally functions in the context of supply chain management:

1. Data Collection and Integration

The first step is collecting data. AI systems in supply chains gather data from multiple sources, such as supply chain visibility tools, IoT sensors, and enterprise resource planning (ERP) systems. This data could include information on inventory levels, transportation routes, order statuses, supplier performance, and even external factors like weather conditions or geopolitical events.

This data is then integrated into an AI-driven platform where it can be processed and analyzed. For businesses, having access to this integrated data in real-time is crucial for quick decision-making and efficient operations.

2. Predictive Analytics and Demand Forecasting

AI uses advanced algorithms to forecast demand by analyzing historical data and identifying patterns. These predictive models can make highly accurate forecasts based on factors such as consumer behavior, seasonality, and even market conditions. For example, AI-driven demand forecasting can help businesses predict which products will be in high demand and adjust their inventory and production schedules accordingly.

For instance, tools like GoTrack can be used to monitor inventory in real-time, and when combined with predictive analytics, businesses can avoid stockouts or overstocking, improving overall operational efficiency.

3. Route Optimization

AI plays a huge role in optimizing logistics and transportation management. By analyzing real-time data like traffic patterns, weather conditions, and delivery schedules, AI can suggest the most efficient routes for delivery drivers. This not only reduces delivery times but also helps businesses save on fuel costs and improve delivery accuracy.

AI-powered tools can also automate route planning, taking into account variables like the number of packages to be delivered, distance, and delivery time windows. These tools are essential for improving logistics efficiency and ensuring that products are delivered on time, without unnecessary delays.

4. Supplier Management and Risk Mitigation

AI also improves supplier management by using machine learning to predict supplier performance and potential risks. By analyzing historical supplier data, AI can identify patterns that suggest potential delays or issues in the supply chain, allowing businesses to take proactive steps to address these challenges before they escalate.

For example, AI can flag suppliers with recurring delivery issues and recommend alternative suppliers, helping businesses avoid disruptions. Supply chain risk management is critical, and AI’s ability to predict and mitigate risks gives businesses a competitive edge by ensuring they remain adaptable in a rapidly changing global market.

Advantages of Using Gen AI in Supply Chain

Generative AI (Gen AI) is a type of AI that focuses on generating new data and ideas based on existing datasets. In supply chain management, Gen AI is becoming a game-changer for several reasons.

1. Improved Forecasting and Planning

One of the main advantages of Gen AI in supply chains is its ability to improve demand forecasting and inventory management. By analyzing historical data and external variables, generative AI creates simulations that predict future demand with great accuracy.

For instance, businesses can use generative AI to model different scenarios (such as supply chain disruptions, price changes, or demand spikes) and determine how those events will affect their operations. This helps businesses make better-informed decisions about production schedules, procurement, and resource allocation.

2. Enhanced Automation and Efficiency

Gen AI can help automate decision-making processes within supply chains. For example, AI-powered automation tools can handle inventory restocking, process invoices, and manage warehouse operations more efficiently than human employees. Automating routine tasks saves time, reduces errors, and frees up employees to focus on more strategic work.

By continuously learning from new data, generative AI can also improve its own decision-making processes over time, making it more efficient and adaptive to changing conditions.

3. Dynamic Pricing and Cost Management

Generative AI can help businesses with dynamic pricing by analyzing factors like market demand, competitor pricing, and inventory levels. AI models can adjust pricing in real-time based on these factors, ensuring businesses maximize their profits while remaining competitive.

Additionally, AI-driven cost management tools can identify areas where businesses are overspending, from procurement to transportation, and suggest cost-saving measures. This helps companies fine-tune their pricing strategies and keep costs in check.

4. Predictive Maintenance and Reduced Downtime

Predictive maintenance powered by AI is another huge advantage for supply chains. By analyzing data from machinery and vehicles, AI can predict when equipment is likely to break down, allowing businesses to perform maintenance before a failure occurs. This reduces downtime, improves productivity, and extends the lifespan of equipment.

For companies in manufacturing or logistics, AI for predictive maintenance helps avoid costly breakdowns and disruptions, ensuring the supply chain operates smoothly at all times.

The Role of AI in the Supply Chain

AI’s role in supply chain management is multi-faceted, spanning several key functions that help businesses become more efficient, responsive, and cost-effective.

1. Supply Chain Visibility

AI provides end-to-end visibility across the supply chain, helping businesses track inventory, shipments, and production schedules in real time. Tools like GoTrack offer supply chain visibility, enabling businesses to make data-driven decisions based on real-time insights.

With AI, businesses can spot potential disruptions, like shipment delays or inventory shortages, and take immediate action to resolve them. This real-time visibility ensures that businesses remain agile and adaptable in a fast-paced market.

2. Process Automation

AI automates many tasks within the supply chain, such as order processing, invoicing, inventory tracking, and route planning. By automating these repetitive tasks, businesses reduce errors, save time, and improve overall efficiency.

For example, automated logistics powered by AI helps businesses streamline their delivery processes, improving customer satisfaction and reducing operational costs. Automation also ensures that tasks are completed quickly and accurately, leaving less room for human error.

3. Advanced Analytics and Decision-Making

AI’s ability to analyze vast amounts of data enables advanced analytics, which helps businesses make better, data-driven decisions. AI-driven insights can highlight trends, detect inefficiencies, and identify opportunities for cost savings, helping businesses optimize their supply chains.

With AI-powered analytics, businesses gain actionable insights that can guide strategic decisions related to production schedules, inventory management, and supplier selection.

Conclusion

AI is undoubtedly changing the way businesses approach supply chain management. It allows companies to optimize their supply chain by enhancing efficiency, reducing costs, and improving decision-making through data-driven insights. As more companies adopt AI, its role in creating smarter, more resilient supply chains will continue to grow.

By leveraging AI-driven tools and generative AI, businesses can improve forecasting accuracy, automate repetitive tasks, and enhance visibility across their operations. However, successful AI adoption requires a strategic approach, ensuring that data is accurate, systems are integrated, and teams are prepared to embrace the technology.

FAQs

How will AI impact sustainability in supply chains?

AI can help improve sustainability by optimizing routes, reducing waste, and minimizing energy consumption. By analyzing data and predicting demand, AI can help companies streamline operations, reduce carbon footprints, and make more sustainable sourcing decisions.

What are the challenges of implementing AI in supply chains?

Key challenges include data integration, high upfront costs, and the need for specialized skills. Additionally, businesses may face resistance to change from employees or a lack of trust in AI-driven decisions. Ensuring quality data and seamless system integration is crucial for successful AI adoption.

How does AI affect cost reduction in supply chains?

AI helps reduce costs by optimizing inventory, automating routine tasks, and improving demand forecasting. It also helps in route optimization, minimizing fuel costs, and predicting maintenance needs, which prevents costly downtime and repairs.

How does AI enhance customer experience in supply chains?

AI enhances customer experience by ensuring timely deliveries, improving order accuracy, and personalizing interactions. It allows businesses to predict demand, avoid stockouts, and track shipments in real-time, which leads to higher customer satisfaction and loyalty.