Top 5 Challenges in Order Management and How to Overcome Them

Most order management problems don’t start big. They start with the wrong stock count, a missed approval, or a late dispatch that no one flagged in time. Small misses pile up. By the time someone notices, it’s already affecting delivery timelines, team bandwidth, and customer commitments.

These issues aren’t solved with more meetings or faster replies. They’re solved when systems give clarity without asking for it, when handoffs are automatic, and when teams don’t need to chase each other for updates. That’s when operations stop reacting and start flowing.

This blog breaks down five challenges that slow things down and 3-4 ways for each to fix them without layering more complexity.

Challenge 1: Inventory Visibility and Accuracy

This is common in logistics-heavy setups. One small mistake in inventory, and the whole chain starts slipping. Dispatch gets stalled. Deliveries are reshuffled. Clients are on call asking what’s taking so long.

And someone’s rushing to cross-check Excel sheets that haven’t been updated since Tuesday. And when your decisions depend on outdated info, everything feels reactive. You’re not managing the orders. You’re chasing them.

Ways to Solve Inventory Visibility and Accuracy Challenges

Now, how do you fix this? Here are some ways:

- Centralized Inventory System: Use a single system that consolidates stock data from all warehouses, suppliers, and in-transit shipments. This removes silos and gives every team (from procurement to fulfillment) the same, accurate view.

- Real-Time Stock Sync: Implement systems that sync inventory levels instantly as goods move. Whether it’s inbound, outbound, or transfers between locations, every change should reflect live. This avoids overpromising or understocking.

- Zone-Based Rolling Audits: Break your warehouse into zones and audit small sections regularly. This catches discrepancies early and avoids the operational freeze that comes with full annual audits. You stay accurate without stopping shipments.

All in all, when your system shows something, everyone from procurement to dispatch should be able to rely on that number without second-guessing it.

GoComet supports this with its comprehensive order management functionality, giving teams a unified view of inventory, orders, and shipments in one system. It cuts out scattered tracking and lets decisions happen with confidence.

Challenge 2: Order Processing Delays

Delays don’t always start at the warehouse gate. Sometimes, they happen the moment an order enters the system. Someone approves late. Another team misses the dispatch window. The system throws an error and no one notices, and ultimately you’re left scrambling.

In high-volume, freight-heavy environments, even a 2-hour lag can push delivery to the next day or worse. Multiply that across hundreds of orders, and you’re sitting on a serious bottleneck.

Ways to Solve Order Processing Delays

- Automated Order Workflows: Manual approvals and data entry create slowdowns. Automate as much of the order lifecycle as possible, from intake to dispatch. Use rules that auto-approve standard orders, auto-generate picking slips, and notify the next team in line.

- Tight SLAs Between Internal Teams: Set internal SLAs between departments. How long does the procurement team get to approve an order? How fast should the warehouse prep it after confirmation? Everyone’s clear. Everyone’s accountable.

- Process Re-Engineering: Map the current process end-to-end. Identify where orders are sitting idle, whether it’s waiting on someone’s approval, a manual data entry, or a confirmation email. Then, rework the flow to reduce touchpoints and dependencies.

- Real-Time Exception Alerts: Not all delays can be prevented. But they can be spotted early. Use systems that trigger alerts when an order has been stuck for too long in a single stage. The faster you catch the anomaly, the easier it is to fix it before it turns into a client issue.

As you can see, delays in order management are rarely about one big failure.

They’re usually death by a thousand cuts. Small gaps, repeated over and over. Fix the workflow, automate what’s predictable, and bring everyone onto the same timeline.

Challenge 3: Communication Gaps Between Departments

Communication breakdowns between departments create silent delays. Sales confirms an order that procurement hasn’t approved. The warehouse never gets the picking list. Logistics shows up for a dispatch no one scheduled.

Everyone thinks someone else is handling it. By the time the confusion is cleared, the window’s missed. A shared system solves half the problem, but only if it can show the right data to the right team.

Ways to Solve Communication Gaps Between Departments

To fix this, you need more than just better habits. Basically, you need a full-fledged system that should offer features like:

- Shared Operational Interface: Give all departments access to the same order management view. Sales, procurement, warehouse, and logistics should see real-time order progress. This removes the dependency on emails and verbal updates.

- Process-Linked Triggers: Set automatic triggers between handoffs. When procurement confirms a PO, the warehouse should be notified instantly. Once picking is complete, logistics should get dispatch instructions without delay.

- Single Source of Comments and Logs: Stop scattering updates across WhatsApp, email, and Excel. Use a system that lets every team drop comments and changes in one place. This makes it easy to trace decisions and catch communication gaps before they turn into operational delays.

To summarize, you need systems that replace scattered updates with shared visibility. GoComet handles this through its customizable dashboard, where each department can configure what they see, so no one is overwhelmed with noise and everyone focuses only on what’s relevant to them.

Challenge 4: Scalability and Flexibility in Operations

Scalability is not just about handling more orders. It’s about handling more without losing control. When order volume increases, the gaps in your system get exposed fast. What worked for 200 orders a month starts breaking at 500. Dispatches get delayed. Approvals stack up. Teams burn out trying to patch what the system can’t handle.

And it’s not just about volume. Flexibility is the other side of the coin. Demand patterns shift. Some SKUs take off overnight. Others stall. A rigid order management system makes it hard to adapt. You either overcommit or underdeliver. Both eat into margins.

Solving Scalability and Flexibility Challenges

Fixing this starts with building for movement. The system needs to flex without falling apart when pressure builds. Here’s what supports that:

- Modular Workflows: Don’t hard-code every process. Build workflows that can flex. For example, high-priority orders should have their own route, approval, and dispatch logic. This keeps critical orders moving even when the standard pipeline is full.

- Cloud-Based, Scalable Infrastructure: Self-hosted, fixed-capacity systems get overwhelmed quickly. Cloud-based platforms scale usage as demand increases. Whether it’s 100 or 10,000 orders, the system adjusts without manual intervention.

- Adaptable Platforms Like GoComet: GoComet is built to handle scale without creating chaos. Its order management tools let you set logic-based rules, view performance in real time, and adjust workflows with zero downtime.

- Central Monitoring with Drill-Down Views: High volume needs more than tracking. It needs control. Use dashboards that let ops leads monitor the overall pipeline but also zoom into problem points fast.

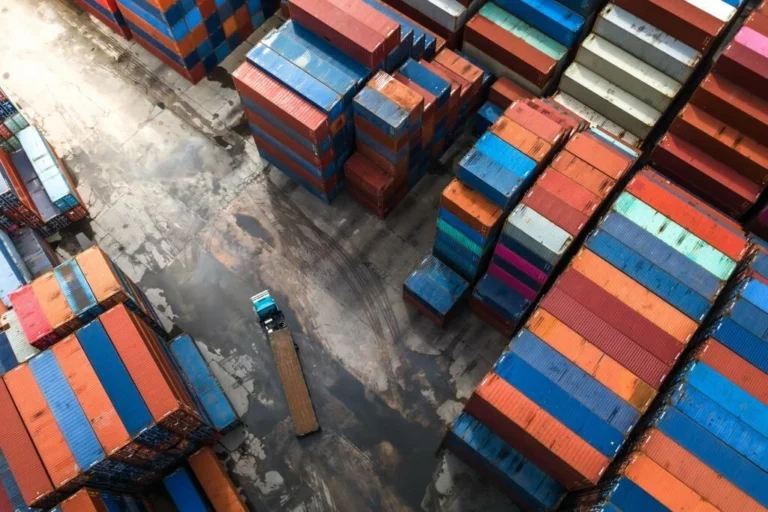

Challenge 5: Integration with Third-Party Logistics (3PL) Providers

You can manage internal operations with structure, but once the shipment moves to a 3PL, visibility often falls apart. Each logistics partner uses their own system. Some send EOD spreadsheets. Others work on portals that don’t connect to your stack. So your team ends up pulling scattered data to guess where the shipment is.

This disconnection creates delays, missed SLAs, and frustrated clients. The only way to avoid it is by bringing 3PL tracking into your system without friction.

Solving Integrations Challenges

Fixing this requires systems that close the loop between internal teams and external partners.

- API-Based System Integration: Use order management tools that connect directly to your 3PL’s systems through APIs. This reduces manual data entry and gives you consistent visibility into pickup times, in-transit status, and proof of delivery.

- Real-Time Shipment Updates: Instead of waiting for EOD reports, get shipment milestones pushed in real time. When goods are picked, scanned, delayed, or delivered, your team sees it immediately. This lets ops make quick decisions and keeps customer teams informed.

- Unified Dashboard for Internal and External Movement: You should not be switching tabs for internal orders versus outsourced shipments. Use a system that shows all orders in one place. Whether it’s handled in-house or by a 3PL, the tracking view should stay consistent.

GoComet makes this easy through real-time shipment integration, pulling live updates from third-party logistics providers directly into your central view. Your team doesn’t need to ask, check, or wait, it’s all visible in one place.

Bottomline

The challenges covered (stock mismatches, processing lags, team silos, scaling issues, and 3PL coordination) are not isolated problems. They are deeply connected. A delay in one area usually triggers issues in another. That is why solving them in parts does not work.

The system needs to be built with end-to-end flow in mind. This is where intelligent platforms like GoComet come in. They bring operations, logistics, and visibility together in one place. With features like real-time updates, automated triggers, integrated dashboards, and customizable workflows, GoComet helps create a setup that scales without breaking and adapts without slowing down. Take your demo now to see how GoComet can help.