What is a Supply Chain Control Tower & How Does it Work?

Table of Contents

Managing a complex supply chain can often feel like handling multiple moving parts. In this blog, we’ll explore how a supply chain control tower can be the solution to optimizing operations. As a centralized platform, it provides real-time visibility, data-driven insights, and advanced decision-making capabilities, giving businesses the tools to proactively manage disruptions, reduce costs, and improve efficiency.

We’ll also dive into the role of AI, machine learning, and automation in transforming supply chain management and how high-level executives can leverage these technologies to stay competitive in today’s fast-paced market.

Understanding the Need for a Supply Chain Control Tower

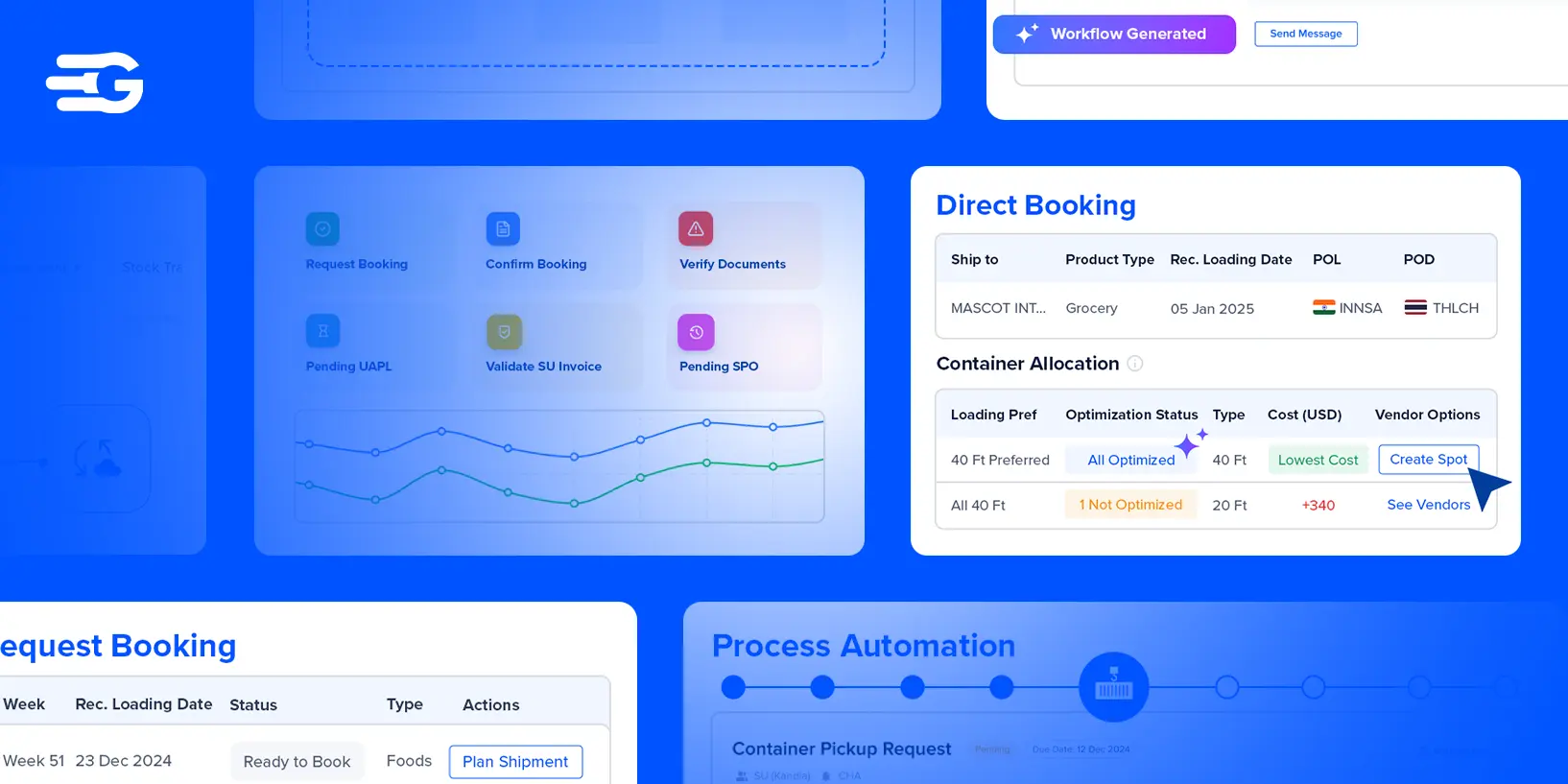

A supply chain control tower is a centralized digital platform that provides real-time visibility into supply chain operations. It collects and analyzes data across logistics, procurement, and inventory management to help businesses track shipments, predict disruptions, and optimize decision-making. By leveraging AI, automation, and predictive analytics, a control tower transforms scattered data into actionable insights, enabling companies to stay agile, reduce costs, and improve efficiency.

Challenges in Modern Supply Chain Management

Managing a supply chain today is like solving a puzzle with missing pieces. Here’s why:

- Too many blind spots: Without full visibility, delays and inefficiencies creep in.

- Scattered data: Teams struggle to collaborate when information is all over the place.

- Bad demand forecasting: Order too much, and you’re stuck with excess inventory. Order too little, and you miss sales opportunities.

- Global disruptions: Whether it’s a pandemic, natural disaster, or port congestion, unexpected events throw supply chains off balance.

The Role of Visibility and Data-Driven Decision-Making

The key to solving these problems? Better visibility and smarter decisions.

- Real-time tracking: Know exactly where your shipments are and act fast when issues arise.

- Advanced analytics: Identify bottlenecks, spot inefficiencies, and make data-backed improvements.

- AI-driven insights: Get predictive recommendations to plan ahead and optimize operations.

Key Features and Benefits of a Supply Chain Control Tower

- Real-Time Data & AI Insights: Combines data from multiple sources into a single dashboard and uses AI-driven alerts to catch problems early.

- Predictive Analytics: Forecasts potential disruptions, improves demand planning, and helps businesses stay ahead.

- Full Supply Chain Visibility: Tracks logistics, procurement, and warehouse operations in real time with live dashboards.

- Automation & Workflow Optimization: Reduces manual processes and streamlines coordination with suppliers, manufacturers, and distributors.

- Cost & Efficiency Gains: Helps companies reduce waste, optimize resources, and manage freight costs, procurement, and inventory.

- Risk Management: Detects supply chain risks early and provides backup plans to handle sudden challenges.

- Seamless Global Collaboration: Enhances real-time communication across teams, suppliers, and partners.

- Competitive Edge: Enables businesses to adapt quickly to market changes and deliver faster, more reliable service.

Types of Supply Chain Control Towers

Supply chain control towers come in different types, each designed for a specific function:

- Operational Control Towers: Keep shipments moving smoothly by tracking logistics, monitoring delays, and ensuring on-time deliveries. These towers help businesses react quickly to supply chain disruptions.

- Analytical Control Towers: Dig into historical data to identify trends, inefficiencies, and cost-saving opportunities. They provide insights that shape long-term supply chain strategies.

- Predictive Control Towers: Use AI and machine learning to anticipate demand fluctuations, potential bottlenecks, and supply chain risks before they happen. This allows companies to make proactive decisions instead of reacting to problems.

- Collaborative Control Towers: Improve coordination between suppliers, manufacturers, logistics providers, and other stakeholders. They centralize communication, reducing misunderstandings and delays.

Challenges in Establishing a Supply Chain Control Tower

Building an effective control tower is more than just about adopting new technology to streamline your operations. It’s about transforming how supply chains operate. Here’s what makes it challenging:

- System Integration Issues: Many companies rely on legacy systems that weren’t built for real-time data sharing. Connecting these with modern control towers requires significant time and effort.

- High Implementation Costs: Setting up a control tower involves investments in software, infrastructure, and skilled personnel. Companies need to ensure that the long-term benefits outweigh the upfront costs.

- Adoption Resistance: Employees and partners may be hesitant to change established workflows. Successful implementation requires proper training and a clear demonstration of how the control tower simplifies their work.

Despite these challenges, businesses that invest in supply chain control towers gain a significant competitive advantage. Greater visibility, better decision-making, and a more resilient supply chain.

Choosing the Right Supply Chain Control Tower Solution

A supply chain control tower solution is only as good as its ability to integrate, scale, and provide real-time insights. Choosing the right one requires a balance between functionality and business needs.

Key Factors to Consider

- Scalability: Can it handle growing order volumes, supplier networks, and new markets? A good control tower should grow with your business.

- Integration Capabilities: Does it seamlessly connect with your ERP, TMS, WMS, and other critical systems? A disconnected control tower can create more problems than it solves.

- Customization: Can it adapt to your specific workflows, data structures, and reporting needs? A one-size-fits-all approach rarely works.

- Data Accuracy and Visibility: Does it provide real-time tracking and analytics? Reliable data is essential for making informed decisions.

- Automation and AI: Does it leverage AI and machine learning for predictive insights, anomaly detection, and automated decision-making?

- User Experience: Are dashboards, reports, and alerts easy to use and actionable? Complicated interfaces slow down adoption and efficiency.

Comparing Top Supply Chain Control Tower Providers

With many solutions available, it’s important to compare them based on real-world effectiveness.

- Features: Look for AI-powered analytics, predictive forecasting, real-time tracking, and automated workflows.

- Pricing: Some platforms charge per shipment, while others have fixed subscriptions. Consider both short-term and long-term costs.

- Implementation Time: How quickly can it be deployed and start delivering value? Some solutions require months of setup, while others integrate in weeks.

- User Reviews and Case Studies: How have other businesses benefited? Look for measurable improvements in efficiency, cost savings, and risk reduction.

Step-by-Step Implementation Guide

A control tower is not just software, it’s a strategy. A structured approach ensures smooth deployment and maximum impact.

- Define Your Goals: Identify specific pain points, whether it’s visibility gaps, delays, or cost inefficiencies. Set measurable objectives.

- Select the Right Platform: Choose a solution that aligns with your industry, shipment volume, and integration needs.

- Ensure System Compatibility: Work with IT teams to integrate the control tower with your existing supply chain systems. Data flow must be seamless.

- Train Your Team: The best technology fails without adoption. Train key stakeholders on how to use the platform effectively.

- Optimize and Scale: Continuously monitor performance, analyze reports, and refine processes to improve efficiency and ROI.

A well-executed control tower implementation transforms supply chain operations. It reduces delays, improves forecasting, and helps businesses respond to disruptions faster.

How AI & Machine Learning Are Revolutionizing Supply Chain Control Towers

AI and machine learning are transforming supply chain control towers from reactive tracking tools into proactive decision-making hubs. Instead of just monitoring shipments, companies can now predict disruptions, optimize inventory, and automate processes in real time. This shift is making supply chains faster, smarter, and more resilient than ever.

AI’s Role in Supply Chain Management

AI is reshaping supply chains by making them faster, smarter, and more efficient. Instead of relying on reactive decisions, companies can now use AI to predict demand, assess risks, and automate processes, reducing delays and cutting costs.

Machine Learning for Smarter Operations

Machine learning takes it a step further by analyzing patterns in logistics, inventory, and demand. It helps companies:

- Optimize inventory levels to prevent stockouts and overstocking.

- Automate real-time decision-making for better supply chain resilience.

- Predict disruptions and suggest the best course of action before issues arise.

With AI and machine learning, supply chain control towers are no longer just about tracking. They’re about predicting, optimizing, and staying ahead of challenges.

Also Read: The Future of Supply Chain Control Towers!

How GoComet Helped Businesses Navigate Red Sea Supply Chain Disruptions

Managing a global supply chain during disruptions isn’t easy. With vital shipping routes like the Red Sea being impacted by geopolitical tensions, companies across industries were facing significant delays, rising costs, and uncertainty. The crisis forced many to reroute shipments and adjust their schedules, creating challenges in production and customer satisfaction.

To tackle these issues, our Supply Chain Control Tower stepped in to provide real-time visibility and predictive insights. This system:

- Provides real-time tracking across all supply chain touchpoints, eliminating uncertainty.

- Uses Predictive ETA to forecast accurate delivery times, helping businesses manage delays proactively.

- Connects teams worldwide with a unified, real-time view of shipments and supply chain status.

The impact? Faster decision-making, minimized losses, and improved customer satisfaction. Companies using GoComet were able to save millions in potential production losses and keep customers informed with accurate delivery estimates.

This approach not only helped businesses navigate the immediate crisis but also built a more resilient and adaptable supply chain for future disruptions.tem is built to grow, even allowing future tracking of carbon emissions to make operations more sustainable.

Conclusion

A supply chain control tower isn’t just a nice-to-have. It’s becoming a must-have for businesses that want to stay ahead of disruptions, optimize operations, and cut costs. With AI, machine learning, and real-time visibility, companies can build a resilient, efficient, and future-ready supply chain.

FAQs

Can Small Businesses Benefit from Control Towers?

Yes. Modern control towers aren’t just for big companies. Cloud-based, affordable solutions give small businesses real-time visibility, better inventory control, and faster decision-making. They help reduce delays, cut costs, and improve efficiency without requiring huge IT investments.

What Industries Use Supply Chain Control Towers?

Almost any industry that relies on logistics and inventory management:

- Retail & E-commerce: Tracks shipments and optimizes fulfillment.

- Manufacturing: Monitors suppliers and production schedules.

- Pharmaceuticals & Healthcare: Ensure timely, compliant deliveries.

- Automotive: Manages complex supplier networks.

- Aerospace & Defense: Enhances logistics for global operations.

- Food & Beverage: Keeps perishable goods moving efficiently.

If supply chain delays cost you money, a control tower can help.