Understanding Drayage: Types, Costs, And Its Role

Table of Contents

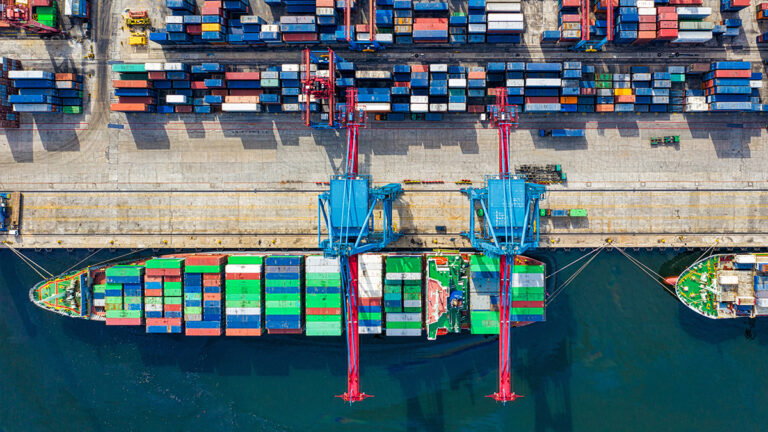

Drayage plays a crucial role in keeping supply chains efficient. It refers to the short-distance movement of goods, such as transporting containers from ports to warehouses or rail terminals. Without it, shipments could face delays and increased costs, impacting overall logistics operations.

What Is Drayage?

Drayage is the transport of cargo over short distances, typically within metropolitan areas, ports, or intermodal terminals. It serves as a vital logistics link, ensuring the smooth transfer of goods between major transportation hubs.

Short-haul trucking helps bridge gaps between long-haul freight and local distribution. Efficient operations reduce congestion at ports and rail yards, improving supply chain efficiency. Key factors influencing its effectiveness include route optimization, carrier availability, and regulatory compliance.

How Does It Work?

Shipments are picked up from one location and delivered to another within the same region. This process helps transfer cargo between different transport modes, such as from a port to a warehouse or distribution center. Strict timeframes and designated zones ensure smooth operations and prevent delays.

By streamlining short-distance freight movement, drayage enhances overall logistics efficiency, minimizing bottlenecks in the supply chain. Understanding its role helps businesses optimize costs and maintain reliable transportation networks.

Why Is It Important?

Efficient freight movement depends on short-distance transport services. Without it, cargo could be stranded at ports, rail yards, or terminals, leading to delays and increased costs. These services optimize transportation, reduce congestion at shipping hubs, and streamline last-mile logistics for global trade.

Types Of Drayage Services

Drayage services are categorized based on their function in freight movement:

- Inter-carrier Transfers: Transfers freight between different carriers, such as moving containers from rail to truck for further transport. This ensures seamless transitions in multimodal logistics.

- Intra-carrier Transfers: Moves cargo within the same carrier’s network, such as transporting goods between a carrier’s terminals or warehouses.

- Pier Transfers: Shuttles shipments from rail terminals to seaports, facilitating export and import operations by connecting different transport modes.

- Shuttle Transfers: Temporarily moves containers to alleviate congestion at ports or terminals, preventing bottlenecks in freight movement.

- Door-to-door Transport: Provides direct transport from the port or terminal to the final destination, eliminating the need for additional handling and reducing transit times.

- Expedited Transport: Prioritizes time-sensitive shipments for faster movement, often required for urgent deliveries.

Each type plays a crucial role in ensuring efficient cargo movement within supply chains.

What Is The Difference Between Freight And Drayage?

Freight is the broader movement of goods over long distances, spanning international and domestic shipments via air, sea, rail, and road. Drayage shipping, in contrast, is a specialized segment of freight that handles short-distance transportation, typically within ports, intermodal terminals, or urban hubs.

While freight involves end-to-end logistics management, drayage ensures the quick transfer of cargo between major transport points, facilitating smoother transitions and preventing delays in the supply chain. Drayage is essential for handling time-sensitive shipments, reducing port congestion, and supporting multimodal transport systems by efficiently linking different freight modes.

Breaking Down Drayage Charges

Drayage costs vary based on multiple factors, including distance traveled, fuel prices, container weight, congestion surcharges, regulatory fees, and labor costs. Additional charges often arise from chassis rentals, storage fees, terminal handling charges, and detention or demurrage penalties when shipments exceed allotted timeframes.

Seasonal demand and port congestion can further drive up expenses. To manage costs effectively, businesses must implement route optimization, carrier negotiations, and real-time shipment tracking to minimize unnecessary expenses and improve overall supply chain efficiency.

The Future Of Drayage

The drayage industry is undergoing significant transformations, driven by technological advancements and sustainability initiatives:

- Market Growth: The U.S. drayage market is projected to grow to $8.3 billion by 2027, propelled by the global surge in e-commerce demand.

- Automation: The adoption of AI-driven software algorithms is revolutionizing load rate determinations in drayage, leading to cost reductions and more competitive pricing.

- Sustainability: The American Trucking Associations reports that over the past three decades, emissions from new trucks have decreased by more than 98%, reflecting the industry’s commitment to environmental sustainability.

These developments underscore a pivotal shift in the drayage industry towards automation and sustainability, with substantial investments and regulatory measures steering the transition to a more efficient and environmentally friendly future.

Wrapping up

Drayage is a critical component of modern logistics, enabling seamless cargo movement between ports, warehouses, and intermodal hubs. Businesses that understand its role, cost factors, and future advancements can optimize their supply chains for efficiency and cost savings. As technology continues to transform drayage operations, companies must stay ahead by leveraging automation and sustainability practices to enhance their logistics strategies.

FAQs

What is an example of a drayage?

Drayage occurs when a truck moves a shipping container from a port to a nearby warehouse or rail terminal. For example, after a container arrives at the Port of Los Angeles, a truck transports it to a distribution center within the city before it continues its journey.

Why is drayage expensive?

Drayage costs are high due to factors such as fuel prices, congestion surcharges, equipment rentals, and labor expenses. Additional fees like terminal handling charges and detention penalties, can further increase costs, especially when delays occur at ports or rail terminals.