Understanding the Fundamentals of Logistics

Global supply chains are under relentless pressure. From soaring costs and shifting consumer expectations to frequent disruptions caused by geopolitics and climate events, the logistics function is no longer a backend operation. It’s now a boardroom priority.

For enterprise supply chain leaders, mastering logistics fundamentals isn’t optional. It’s the foundation for staying agile, reducing inefficiencies, and driving long-term growth in a volatile environment. This isn’t a refresher. It’s a strategic reset for how logistics operations can evolve to deliver real business value.

What is Logistics?

Logistics refers to the process of planning, implementing, and managing the flow and storage of goods, services, and related data across the supply chain-from suppliers to customers.

As defined by Michigan State University, logistics ensures goods arrive at the right location, at the right time, in the right condition, and at the right cost. It plays a critical role in enabling smooth, responsive, and cost-effective supply chains.

But logistics today involves far more than transportation and warehousing. It encompasses real-time data, interdepartmental coordination, technology integration, and strategic decision-making. Without robust logistics, even the most well-funded supply chains risk underperformance.

Key Objectives of Logistics

Effective logistics operations support enterprise supply chain goals in several ways:

- Customer satisfaction: Delivering the right product at the right time builds trust and loyalty.

- Cost efficiency: Reducing waste, transport costs, and idle time saves millions annually.

- Inventory optimization: Aligning stock levels with actual demand prevents overstocking and shortages.

- Agility and responsiveness: Rapidly adapting to disruptions, delays, or market shifts keeps business continuity intact.

When logistics objectives are aligned with broader business strategy, they create measurable advantages in profitability, resilience, and service levels.

Core Components of Logistics

Strong logistics performance is built on a few essential components:

Transportation

Movement of goods using road, sea, air, or rail. Selecting the right mode and carrier-based on cost, reliability, and speed-is fundamental to operational efficiency.

Warehousing

Safe, organized storage of goods, either as buffer stock or as part of distribution operations. Smart warehouse design and automation play a big role in reducing labor and delays.

Inventory Control

Maintaining optimal stock levels using forecasting tools, safety stock buffers, and real-time visibility into SKU-level performance. This helps avoid stockouts or excess carrying costs.

Order Fulfillment

Managing the complete lifecycle of a customer order-from placement to delivery. Accuracy, speed, and reliability here are directly linked to customer satisfaction.

Information Management

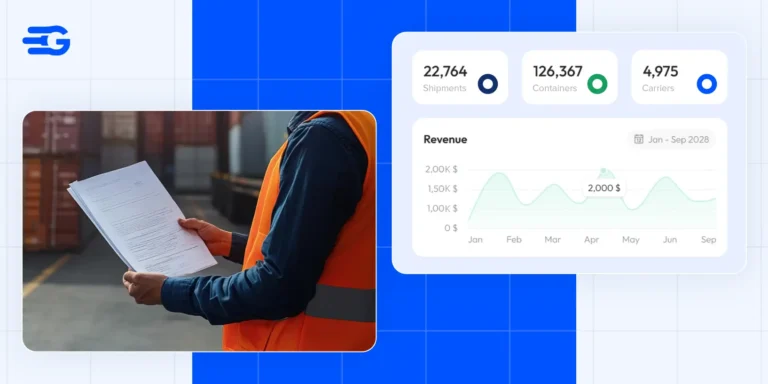

Data is now a logistics resource. Platforms like GoTrack, GoComet’s real-time tracking module, help leaders monitor global shipments, identify risks, and make informed decisions based on live data.

Logistics Processes and Flow

Understanding the flow of logistics processes helps identify bottlenecks and areas for improvement:

Procurement

Sourcing raw materials or finished goods at the best terms. Strategic procurement ties directly into logistics when it comes to shipping terms, timelines, and cost predictability.

Inbound Logistics

Receiving goods into warehouses or factories. Efficiency here affects production lead times and cost-per-unit.

Outbound Logistics

Delivering finished goods to customers, retailers, or distribution partners. It’s the final step and often the most visible to the customer.

Reverse Logistics

Handling product returns, recycling, or disposal. Increasingly, reverse logistics also includes sustainability reporting and circular supply chain practices.

Essentra’s Cost-Efficient Logistics and Visibility Saved 20+ Hours Monthly

Essentra, a global manufacturer operating across 25+ countries, faced several operational barriers that impacted its logistics efficiency. Manual processes delayed vendor payments and limited visibility into freight movement, making it hard to optimize routes or make informed decisions.

By deploying GoTrack, GoInvoice, GoShipment, and GoProcure, Essentra:

- Reduced freight spend by 4.34%, thanks to smarter procurement and rate benchmarking

- Saved 20+ hours monthly with centralized invoice reconciliation

- Improved vendor participation in RFQs through streamlined, automated bidding tools

- Cut invoice errors with OCR-powered automation via GoInvoice

- Used real-time dashboards to improve responsiveness and track key performance metrics

This transformation shows the power of integrating digital tools into core logistics operations. Read the full case study.

Best Practices in Logistics Management

To maintain a high-performing logistics function, enterprise teams focus on proven strategies:

Technology Integration

Automation and integration reduce manual effort and increase visibility. Tools like GoComet’s TMS unify procurement, shipment tracking, and performance data across departments.

Performance Monitoring

Key metrics such as OTIF (On-Time-In-Full), cost-per-shipment, and carrier reliability must be actively tracked. Visibility into these numbers helps drive improvements.

Supplier Collaboration

Strengthening communication with suppliers leads to fewer delays, better negotiation outcomes, and higher service quality.

Continuous Improvement

Logistics must evolve. Regular audits, stakeholder feedback, and post-mortem analyses of disruptions help fine-tune strategy and execution.

“The logistics and supply chain industry faces challenges like fragmented visibility, inefficiencies in freight procurement, unpredictable shipping costs, and delays due to manual processes, which GoComet addresses by offering AI-driven tools to streamline operations, provide real-time tracking, and optimize procurement for cost efficiency.” – Pramod Pardale, the Head of supply chain operations at VVF

Final Thoughts

For enterprise supply chain leaders, understanding logistics fundamentals is more than academic, it’s mission-critical. As supply chains grow more complex, success hinges on how well you manage logistics planning, execution, and visibility.

Whether you’re rethinking your transportation strategy, introducing automation, or building resilience into your vendor network, a strong logistics foundation helps you move from reactive firefighting to proactive performance.

At GoComet, we’ve helped hundreds of global organizations transform their logistics workflows into efficient, data-driven systems that scale.