Enhance Your Supply Chain With Procurement Analytics

Procurement analytics can be a game-changer for businesses looking to optimize their supply chains. When applied correctly, it provides clear, actionable data that helps companies improve efficiency, reduce costs, and strengthen relationships with suppliers. Let’s dive into the essential aspects of procurement analytics and how it can enhance your supply chain operations.

What is Procurement Analytics?

Procurement analytics involves collecting, analyzing, and interpreting procurement-related data to help businesses make better decisions. It moves companies from reacting to situations toward anticipating and managing challenges proactively. In simple terms, it allows companies to understand spending patterns, evaluate supplier performance, and identify cost-saving opportunities before they become critical.

If a business regularly experiences delays with a supplier, procurement analytics can help identify the root causes, whether it’s delivery times or quality issues. This leads to more informed decision-making that ultimately boosts the efficiency of the supply chain.

Why Is Procurement Analytics Crucial for Supply Chains?

In the fast-paced world of supply chain management, businesses face constant challenges. From managing fluctuating costs to meeting compliance standards, procurement analytics is designed to address these issues.

With procurement analytics, you can improve operational efficiency by identifying inefficiencies in processes. For instance, if your company has recurring bottlenecks, data can point to exactly where and why these delays occur, allowing you to take action.

Moreover, procurement analytics can reduce risk. It helps you pinpoint areas in your supply chain where risks like supply shortages or price fluctuations could occur. It then provides you with data to mitigate these risks before they escalate into bigger problems.

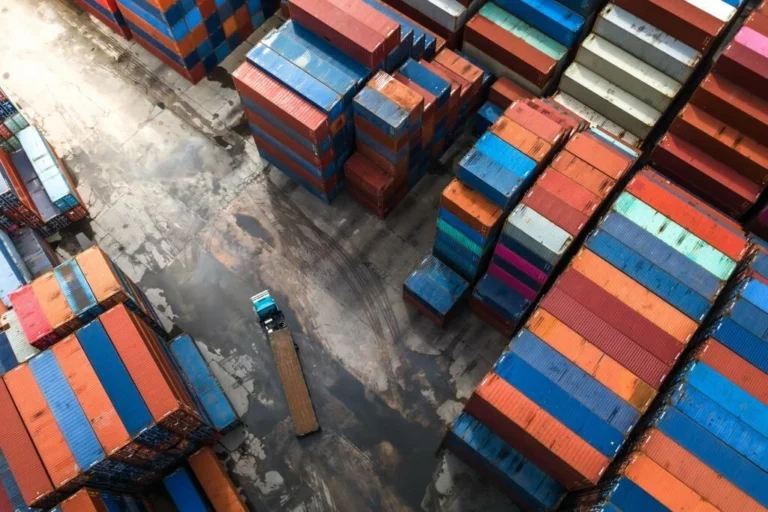

How Procurement Analytics Works

The process of procurement analytics is straightforward, but it requires integration and a structured approach. Here’s how it works in a typical supply chain.

Data Collection and Integration

The first step in procurement analytics is gathering data from various sources. These could include supplier databases, ERP systems, and even external sources like market trends. The more data you have, the better the analysis will be.

A company that tracks inventory levels, supplier performance, and market price fluctuations. By pulling all this data together, the company gains a better understanding of where their money is being spent and how suppliers are performing.

Data Cleansing and Transformation

Once the data is collected, it needs to be cleaned and organized. Data can often be messy, with missing entries or inconsistent formatting. This stage ensures that the data is accurate and categorized correctly for meaningful analysis.

This process is crucial. Imagine trying to make decisions based on incorrect or incomplete data; it’s easy to see how that could lead to costly mistakes. By focusing on data accuracy, procurement analytics ensures that every decision you make is based on reliable information.

Advanced Analytics and Visualization

After data cleaning, advanced analytics comes into play. AI tools and algorithms can identify trends and anomalies within the data. These tools turn raw data into actionable insights, often presented through easy-to-understand charts and graphs.

You could quickly spot a supplier whose pricing is consistently higher than others, or discover a trend in your inventory levels that could lead to stockouts.

Key Components of Procurement Analytics

Understanding the core components of procurement analytics will help you apply the strategy more effectively to your supply chain.

1. Spend Analysis

Spend analysis tracks historical purchasing data, helping businesses identify spending patterns. This data can be broken down by category, supplier, and department, offering clarity on where the money is going.

By consolidating purchases across departments, businesses can leverage economies of scale. For example, if multiple departments are buying similar items from different suppliers, consolidating the orders with one supplier can often lead to cost savings.

2. Supplier Performance Evaluation

Supplier performance evaluation is critical for long-term supply chain success. Procurement analytics helps track key performance indicators (KPIs) such as delivery times, quality of goods, and pricing consistency.

A company that tracks supplier performance over time can spot underperforming suppliers early. If a supplier consistently fails to meet quality standards or delivery deadlines, procurement analytics can help identify alternatives or renegotiate terms.

3. Cost Reduction Strategies

Procurement analytics offers valuable tools for cost reduction. By optimizing inventory levels, businesses can avoid overstocking, which ties up capital and leads to higher storage costs. Similarly, it can help streamline sourcing initiatives to secure better pricing and improve product specifications.

One personal example I’ve seen: a company that was dealing with excessive inventory discovered that they were over-ordering due to inaccurate demand forecasting. With procurement analytics, they optimized their purchasing process and reduced inventory costs by 15% in just six months.

Types of Procurement Analytics

There are different types of procurement analytics that serve various purposes.

Descriptive Analytics

Descriptive analytics helps businesses understand past performance. By analyzing historical procurement data, companies can identify trends and patterns that give them a clearer view of what’s worked well and what hasn’t.

For instance, if you want to know how often a supplier has failed to meet delivery dates in the past year, descriptive analytics will provide that data clearly.

Predictive Analytics

Predictive analytics goes a step further. By looking at historical data, it forecasts future trends and potential disruptions. This enables companies to prepare for upcoming challenges.

Let’s say your company relies on a particular raw material that’s prone to price fluctuations. Predictive analytics can alert you when prices are likely to rise, giving you time to make adjustments to your procurement strategy.

Prescriptive Analytics

Prescriptive analytics recommends actions based on the data. After analyzing past and predicted data, it provides solutions to achieve desired outcomes. If analytics predict a potential shortage, prescriptive tools might recommend increasing orders or finding alternative suppliers.

Benefits of Procurement Analytics

Implementing procurement analytics can bring immediate benefits to your business.

Improved Decision-Making

Real-time data means better decision-making. If you’re in the middle of contract negotiations with a supplier, procurement analytics provides the data you need to ensure you’re getting the best deal.

We worked with a business that benefited greatly from procurement analytics. It helped them company during a contract renewal. With access to detailed performance data, they were able to renegotiate terms with their supplier, cutting costs by 10%.

Enhanced Supplier Relationships

When suppliers know that you’re tracking their performance and can share feedback, it fosters trust and collaboration. Supplier relationships become more transparent, and both parties can work together to resolve issues before they become major problems.

Think about it: when a supplier sees that you’re actively using data to manage your relationship, they’re more likely to be responsive and make improvements.

Increased Operational Efficiency

Procurement analytics identifies bottlenecks in supply chain operations. Whether it’s inefficient processes or missed deadlines, analytics highlights areas for improvement. By acting on this information, you can streamline operations and reduce delays.

Implementing Procurement Analytics in Your Supply Chain

To fully benefit from procurement analytics, businesses must implement it effectively. Here’s how:

Define Clear Objectives

Start by defining what you want to achieve. Are you looking to reduce costs, improve supplier performance, or enhance inventory management? Knowing your objectives will help you focus your analytics efforts on the most important areas.

Companies that aimed to improve supplier performance, focused on tracking delivery times and quality metrics first.

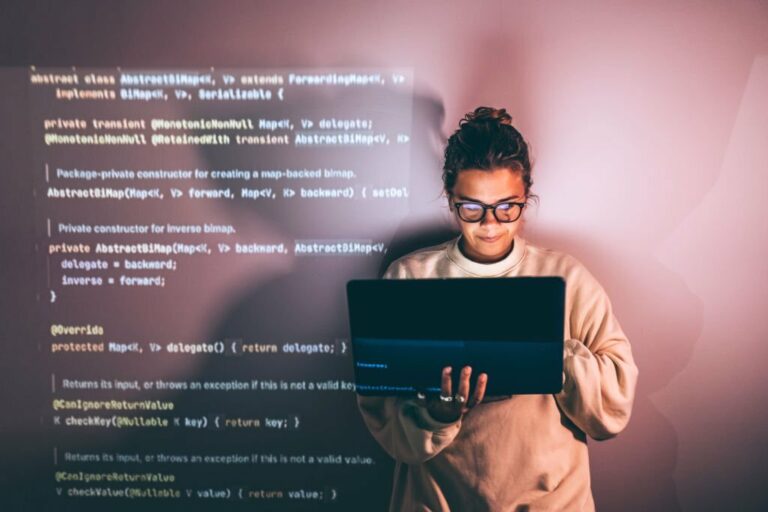

Choose the Right Tools

It’s important to select the right procurement analytics tools. Platforms like GoComet integrate with existing systems and provide actionable data. These tools help businesses collect, analyze, and act on procurement data more efficiently.

Train Your Teams

To get the most out of procurement analytics, your teams must be equipped to use the tools effectively. Training staff on how to interpret the data and apply it in their daily tasks will ensure your analytics efforts lead to real results.

The Future of Procurement Analytics

Procurement analytics is advancing rapidly. As businesses face more complex supply chains, these tools will only become more critical.

AI and Machine Learning

AI and machine learning are changing how procurement works. These technologies help businesses automate tasks that used to take time. AI can predict supplier behavior by analyzing past data.

It can forecast price hikes, delivery delays, and other risks. This allows companies to prepare ahead of time. Machine learning refines pricing strategies by continuously learning from market trends. This ensures smarter purchasing decisions and cost control.

Sustainability Metrics

Sustainability is increasingly important in procurement. Procurement analytics now includes tools to track carbon emissions, resource use, and waste. Companies can use this data to make environmentally responsible decisions. They might choose suppliers who meet certain sustainability standards. As sustainability regulations grow stricter, this tool will help businesses stay compliant and avoid penalties.

Predictive Capabilities

Predictive analytics helps businesses stay ahead of disruptions. By looking at historical data, it forecasts supply chain risks like delays or price changes. Companies can then adjust their strategies to avoid problems.

Predictive tools can help manage inventory better and negotiate smarter contracts with suppliers. This reduces the chances of stockouts or delays, leading to cost savings and smoother operations.

Final Thoughts

Procurement analytics is essential for businesses looking to streamline their supply chains and stay competitive. By adopting data-driven decision-making, companies can reduce costs, improve supplier relationships, and enhance overall operational efficiency. If your company isn’t yet leveraging procurement analytics, now is the time to start. Unlock the power of procurement analytics and take control of your supply chain like never before.